The company ZIKO is a representative of leading European manufacturers of pasteurizers and sterilizers.

Many factors have contributed to the development of the dairy industry as we know it today. Countless hours have been devoted to analyzing production processes and improving them. Many objectives would not have been achieved without human effort, dedication, and ingenuity. Often, at the very foundation lie techniques and technologies that passed their first successful laboratory tests as far back as two centuries ago. One of these is the technique known as milk pasteurization, without which it is difficult to imagine the modern food industry, including dairy production.

Milk pasteurization has been refined over time and adapted to increasingly large-scale food production. This led to the development of appropriate equipment — pasteurizers — designed to be installed on production lines for manufacturing essential food products such as milk and dairy products.

Milk pasteurization is a process aimed at eliminating microorganisms from the product, with particular emphasis on pathogenic forms that pose a threat to consumers. In food production, maintaining consumer health safety is critically important, especially in large-scale food distribution. The name of the process comes from its pioneer, Louis Pasteur, who lived in the 19th century. The researcher discovered the positive effect of thermal food treatment, which significantly extends shelf life.

Milk pasteurization is combined with other methods such as homogenization, membrane filtration, or centrifugation. In general, pasteurization is a food preservation process designed to destroy or inhibit the growth of pathogenic microorganisms and enzymes, while paying special attention to preserving the taste and nutritional value of products as unchanged as possible and preventing recontamination. During pasteurization, beneficial microorganisms are also destroyed.

In simple terms, milk pasteurization is the process of heating milk for a specific period of time. In general, two types of pasteurization can be distinguished: low-temperature pasteurization and high-temperature pasteurization. The differences between them are determined by variations in process parameters, namely time and temperature.

Low-temperature pasteurization of milk is also known as long-time pasteurization or LTLT pasteurization. LTLT (Low Temperature Long Time) pasteurization, as the name suggests, involves prolonged exposure to a relatively low temperature. In this case, thermal treatment lasts approximately 30 minutes at 63°C.

High-temperature milk pasteurization, also known as HTST (High Temperature Short Time) pasteurization, involves exposure to a higher temperature for a shorter period. The selection of process parameters in this case depends on the quality of raw milk. Typically, milk is heated to 72–75°C and held under these conditions for approximately 15–20 seconds.

In the case of cream pasteurization, which is subsequently used, for example, in butter production, pasteurizers are set to a temperature of approximately 92°C for 30–40 seconds. The change in parameters for this raw material is due to its high fat content. The protective role of fat lies in forming a specific water-free оболонка around microorganism cells, which complicates the pasteurization process and necessitates adjustments to its parameters.

Milk pasteurization ensures the destruction of heat-sensitive microorganisms, including yeasts, molds, and bacteria that do not form endospores. Microorganisms present in milk that may negatively affect human health can be characterized by parameters defining their thermal resistance. These parameters are specific to a given bacterial species and may vary depending on environmental conditions and within a given population.

The resistance of microorganisms to heat depends on the environment in which they are present. In milk, their thermal resistance is influenced by water activity, pH, fat content, and protein content. Milk is an aqueous medium for microorganisms, and the destructive effect of heat increases as the dry matter content decreases. The number of microorganisms that survive thermal destruction at a constant temperature follows a logarithmic relationship. According to literature data, this logarithmic nature of microbial inactivation leads to important conclusions applicable in laboratory practice: when the initial number of microorganisms in raw material is high, i.e. when milk has a high initial microbial load, the heating time at a constant temperature must be extended (the higher the temperature, the faster bacteria are destroyed) to achieve the required microbiological purity of the product, meaning the desired reduction in the number of microorganisms.

It is also important to note that it is impossible to destroy all cells completely, as this would require infinite heating time. Therefore, the effectiveness of milk pasteurization is generally estimated at approximately 99%. The presence of microorganisms in milk poses a risk to consumer health, which is why pasteurization aims to eliminate as many of them as possible. Consequently, it is crucial to determine the success of pasteurization and confirm its effectiveness.

So, how can we prove that the pasteurization process for milk and dairy products has been carried out correctly? The effectiveness of pasteurization in the finished product is confirmed by determining the activity of a naturally occurring milk enzyme — alkaline phosphatase (ALP). This enzyme is inactivated at high temperatures.

According to current regulatory requirements, the activity of ALP in pasteurized cow’s milk is limited and must not exceed 350 mU/l. Alkaline phosphatase is not the only enzyme sensitive to high temperatures. Research has shown that gamma-glutamyl transferase and lactoperoxidase are also reliable indicators of pasteurization efficiency and proper thermal treatment conditions for milk and dairy products. This is because the thermal resistance of these enzymes is higher than that of most non-spore-forming microorganisms found in milk.

Alkaline phosphatase activity depends, among other factors, on the fat content of milk, the cattle breed, and the type of feed used. As mentioned earlier, the presence of ALP in milk after pasteurization indicates insufficient process quality. The amount of ALP remaining after pasteurization is referred to as residual phosphatase, and testing for ALP activity has become a standard method for monitoring pasteurization effectiveness.

ALP activity can be determined using classical colorimetric methods, as well as instrumental analyses based on radiation measurements, such as chemiluminescence or fluorometric analysis, or tests based on electrochemical reactions, including amperometric and potentiometric methods, as well as rapid test strips. However, rapid test strips do not allow for quantitative determination of the enzyme.

In the dairy industry, it is extremely important to control thermal processing conditions, as they often represent a critical control point in the production of finished products. Today, in modern dairy processing plants, pasteurization is carried out as part of an integrated technological line alongside processes such as homogenization and centrifugation.

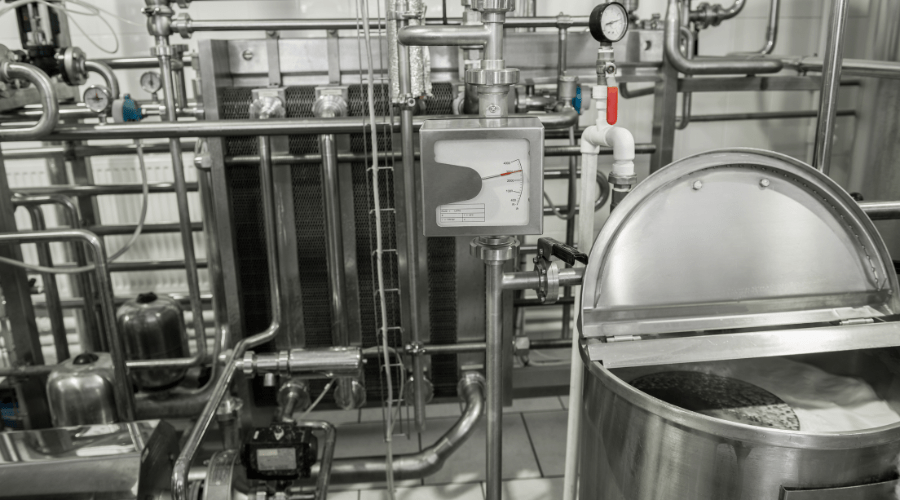

Milk pasteurization is carried out in devices called pasteurizers. Milk is transported through pipelines into the pasteurizer after the pumps are started. Pasteurizers can operate in batch or continuous mode. A prerequisite for heat flow is the occurrence of a temperature gradient — heat is transferred from a fluid with a higher temperature to a fluid with a lower temperature.

The most commonly used heat exchanger in the dairy industry is the plate pasteurizer. This solution involves mounting a series of plates arranged in parallel on a supporting frame. The heating medium is hot water. The pasteurized product — milk — flows in so-called counter-current flow relative to the heating medium. This solution ensures more efficient heat exchange between fluids. The liquids move through channel spaces formed between the plates, which separate the heating medium from the pasteurized liquid.

Modern solutions provide for dividing the plates of the heat exchanger into sections, each of which performs a specific function within the overall pasteurization process.

The following sections can be distinguished:

- a section where water is heated by steam;

- a milk pasteurization section, where the core of the process takes place — heating milk with hot water from the previous section to the pasteurization temperature;

- a holding section consisting of plates with deep channels, where milk heated to the pasteurization temperature is held at this temperature for a specified time of 15 to 30 seconds;

- a heat regeneration section consisting of two or three sections, in which cold milk entering the pasteurizer is preheated by heat recovered from hot milk leaving the holding section.

In addition, there is a two-section cooling stage for further cooling of pasteurized milk, first with cold water and then with ice water.

Plate heat exchangers offer a number of advantages. The most important include: a high level of heat recovery in the regeneration section — reaching 80–90%, which results in significant energy savings; the ability to control system efficiency by adjusting the number of plates in individual sections; ease of operation; ease of cleaning; and the ability to pasteurize, in addition to milk, many other liquid and semi-liquid products, such as cream. The use of a holding section is optional, and partial milk degassing is also possible. Modern plate pasteurizers available on the market are equipped with design elements that maintain the set pasteurization temperature and systems that automatically divert milk if it has not been sufficiently pasteurized.

The compact design of plate heat exchangers means they require relatively little installation space. The plates are thin, metal, and corrosion-resistant. They are joined together either by brazing or using a tightening frame. The plates are arranged in such a configuration that openings in their upper and lower corners form flow channels. Flow control within the channels is achieved using gaskets around the openings, separating the flows from one another. The hot medium flows on one side of the plate, while the cold medium flows on the other. Heat exchange between the fluids occurs without direct contact, with both fluids flowing in counter-current arrangement.

The surfaces of heat exchanger plates are embossed with various patterns. This increases flow turbulence for both fluids at relatively low flow velocities during milk pasteurization. Increased turbulence improves heat transfer coefficients and reduces the formation of deposits from the liquid. Turbulent flow supports heat diffusion and prevents the formation of temperature layers characteristic of laminar flow. Heat transfer coefficients in plate heat exchangers can be up to twice as high as those in shell-and-tube exchangers.

The counter-current flow system can be series, parallel, or mixed. These design concepts aim to direct the flow on both sides of the plates so that the fluids undergo multiple changes in flow direction. In a series configuration, the flow path is long, resulting in high hydraulic resistance at relatively low flow velocity. In a parallel system, the flow path is short — equal to the length of a single channel — resulting in a low pressure drop.

To combine the advantages of both solutions, mixed systems are used. In such systems, the desired flow velocity is achieved through plates with parallel channels, while plates with series channels ensure the required temperature change of the media in both circuits.

Plate heat exchangers must be cleaned in accordance with manufacturer recommendations and using approved cleaning agents to avoid undesirable side effects, such as microscopic surface damage to the plates that is not visible to the naked eye.

To ensure optimal control of thermal food preservation, modern dairy plants use computer-based pasteurization process control, consisting of properly programmed controllers. Dedicated software monitors all parameters related to correct process execution, enabling full control over the technological process and line operation. If critical values are exceeded, the system triggers an alarm and initiates procedures to prevent further production of defective product. Milk that does not meet specified parameters can be redirected for re-pasteurization. Automated line control with process visualization not only simplifies operation but also enables analysis of archived process data, which can be useful for production planning and reporting.

Within automated supervision of the pasteurization line, the controller is responsible, among other tasks, for: controlling pumps and valves; monitoring, recording, and regulating pasteurization temperature; controlling outlet product temperature; monitoring outlet pressure; and storing and archiving operating modes and parameters on a computer disk. Visualization of line operation using graphical and textual elements facilitates real-time process monitoring and parameter analysis.

The market offers a wide range of heat exchangers from manufacturers and suppliers such as Spomasz Bełżyce, Alfa Laval, GEA, Sondex, and Tetra Pak. Physical properties of the fluid — such as viscosity, density, and specific heat capacity — affect heat exchanger efficiency and configuration, and thus determine the selection of the most suitable device. To correctly select a heat exchanger, a number of parameters must be defined, including: type and properties of the medium, inlet and outlet temperatures, flow velocity and volume, minimum, maximum, and operating pressure, allowable pressure drop, resistance related to deposits, as well as financial considerations.

Many companies offer support in selecting a heat exchanger that will perform optimally under given process conditions and be properly sized for the application. The range of possible design configurations is extensive, making it possible to adapt equipment to virtually any operating conditions. The key priority remains ensuring process repeatability and microbiological safety, which are critical in food production.

For consultation regarding technical specifications, equipment availability, and pricing, please submit a request on our website or contact us by phone using the numbers listed in the Contacts section.