The company ZIKO offers ready-made modular metal-plastic tanks for the storage of mildly aggressive substances, UAN (urea–ammonium nitrate solutions), molasses, oil, as well as technical and drinking water.

We also design, manufacture, and install tanks individually, in various types and capacities, according to customer requirements. A 5-year quality warranty is provided for all manufacturing materials, finished structures, and installation services.

What modular metal-plastic tanks are and what they are used for

Quick-assembly modular metal-plastic tanks are specialized technological reservoirs designed for storing large volumes of various liquids — from ordinary water to mildly aggressive substances. Their frames are made of galvanized steel sheets, which ensures high mechanical strength. Inside, the structures are sealed with special polypropylene plastic membranes, providing full water tightness of the tanks.

Purpose of modular metal-plastic tanks

Quick-assembly modular tanks of various types and capacities are used:

- As drinking water reservoirs for water supply systems of cities, towns, and villages.

- For storing large volumes of drinking and technical water in agriculture and at industrial facilities.

- As tanks for safe and long-term storage of molasses and oil at enterprises engaged in sugar beet and sunflower processing.

- As water reservoirs in fire protection systems of industrial facilities, individual buildings, and structures.

- For large-volume storage of UAN (urea–ammonium nitrate solutions), other liquid mineral fertilizers, mildly aggressive substances, and acids.

Modular metal-plastic tanks are also widely used as basins for breeding and cultivating various species of fish, mussels, and crayfish.

Components of a modular tank structure

The structure of a modular tank consists of several elements that ensure structural strength, tightness of the tank, and protection of stored liquids from the negative effects of sunlight and precipitation:

- Concrete foundation, minimum thickness — 40 cm. It must extend 20–40 cm beyond the tank diameter. A strip foundation may also be used as the base.

- Frame. For small tanks with a capacity of up to 100 m³, flat metal sheets are used as the structural base. For larger tanks, galvanized corrugated steel sheets with a thickness of 1–4 mm are applied. This material offers high strength and excellent corrosion resistance, significantly reinforcing the structure and extending its service life.

- Sealing tank membrane made of black polypropylene. This is a UV-stabilized material with a thickness of 0.6–0.75 mm, certified for the storage of food products and drinking water.

- Piping connections — galvanized threaded pipes with nuts, diameter 32–250 mm.

- Roof. Can be manufactured from two materials: galvanized metal or plastic (polypropylene or PVC).

- Configuration options: equipment for filling, draining, and transferring liquids. Additional components may include ladders, level sensors, measuring scales, pumps, ventilation nozzles, valves, floats, and other accessories.

If, during operation of a modular metal-plastic tank, it is necessary to minimize heat loss, the tank can be thermally insulated and equipped with liquid heating systems for winter operation.

Types of modular tanks

Depending on design features, configuration, and purpose, the modular tanks offered by our company can be divided into four types:

- Above-ground tanks without a roof. Intended for seasonal outdoor use or indoor installation.

- Above-ground tanks with a plastic roof. Also designed for indoor operation or seasonal outdoor use.

- Above-ground tanks with a metal roof, suitable for year-round outdoor operation.

- Underground tanks with a metal roof and insulation, primarily intended for storing large volumes of water in firefighting systems.

Advantages of modular metal-plastic tanks

The main advantages of modular tanks are structural strength, practicality, and ease of operation. It is also worth highlighting the following benefits of our tanks:

• Long service life. All types of modular tanks are supplied with a 5-year quality warranty. The potential service life is 25 years or more.

• Affordable price. The cost of modular tanks offered by our company is 2–3 times lower than that of tanks with similar design and capacity from other manufacturers.

• High quality and durability of materials. The frames are made of high-quality galvanized steel, which ensures high structural strength, prevents corrosion-related damage, and extends the service life of the tanks. The membranes are made of polypropylene, a material certified for storing drinking water and food-grade liquids. The plastic is resistant to acids and mildly aggressive substances. The tanks can store water heated up to 110 °C.

• Ease of installation, dismantling, and transportation. The structures are assembled within 1 to 21 days (depending on capacity and configuration). They can be installed even in hard-to-access locations and indoors. The tanks are easy and quick to dismantle, take up little space when disassembled, and can be transported by standard freight vehicles without the use of special equipment.

• High structural strength. The tanks withstand high wind loads (up to 45 m/s) and remain intact during tornadoes, hurricanes, and earthquakes.

• Wide range of standard sizes (approximately 400 models) and capacities: from 18 m³ to 1,219 m³ for underground tanks and from 18 m³ to 4,177 m³ for above-ground tanks.

Modular metal-plastic tanks can be custom-equipped with various additional components. Depending on customer requirements and technological process needs, inlet, outlet, and drain openings of various diameters can be installed at any required location on the tank. The structures can be equipped with liquid level sensors, external ladders, and thermal insulation. Additionally, electric heating elements (heaters) for liquid heating and other equipment may be installed.

Areas of application of modular tanks:

• fire protection systems — for storing sufficient volumes of water required for firefighting;

• storage and distribution of UAN (urea–ammonium nitrate solutions);

• water supply systems for populated areas;

• storage of molasses and oil at industrial enterprises;

• tanks for accumulation and storage of large water reserves;

• wastewater and contaminated water treatment systems;

• basins for breeding and cultivation of fish, crayfish, and mussels.

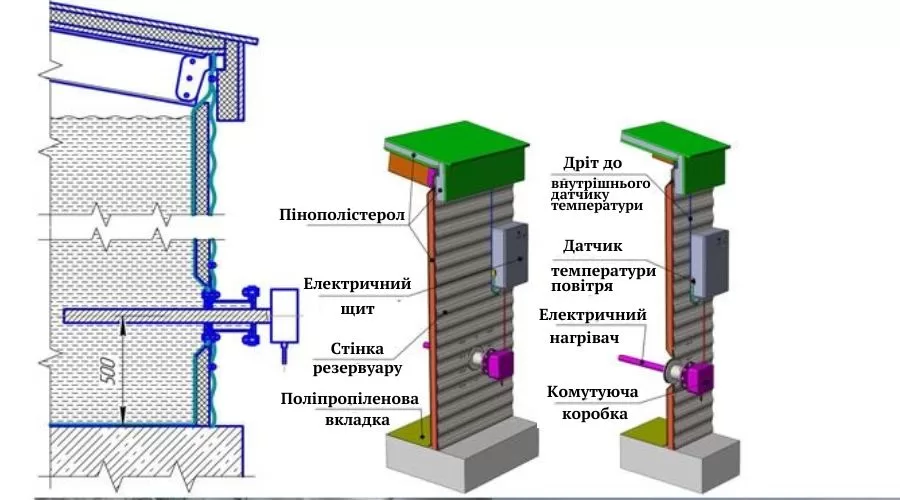

Thermal insulation and equipping tanks with liquid heating systems for winter operation

To reduce heat loss during winter operation, the tanks are thermally insulated and equipped with liquid heating systems. Mineral wool with a density of 80–110 kg/m³ and a thickness of 50–140 mm is glued to the galvanized frame from the inside. The insulation layer is covered with geotextile, after which the membrane is installed.

For liquid heating during the winter period, the tank is equipped with electric heating elements (heaters), temperature sensors, and an automatic control system. When the ambient temperature drops to +1 °C, the control system automatically activates the heaters. Once the water or other liquid reaches the set temperature, the sensors transmit information to the control system, which then switches off the heating elements.

Interested in our offer? Would you like to receive more information about the materials, technical characteristics, and applications of modular metal-plastic tanks?

Submit a consultation request via the feedback form on our website, call us, or send us a message. We will contact you in any convenient way and answer all your questions.