The engineering company ZIKO offers ready-made solutions for physicochemical, biological, and mechanical treatment of wastewater from industrial facilities and sewerage systems. A detailed analysis of the effluent is carried out, based on which treatment systems are designed, equipment is selected, and appropriate water treatment methods are defined.

Company specialists install, service, and repair mechanical wastewater treatment units and provide professional консультації on equipment selection. A quality guarantee is provided for the full range of services.

Mechanical Wastewater Treatment Methods

During mechanical wastewater treatment, solid and suspended particles are removed from the medium. This is a preliminary stage of wastewater preparation prior to discharge or reuse, during which the effluent is prepared for subsequent biological or physicochemical treatment.

The main mechanical methods for wastewater treatment at industrial enterprises and sewerage systems include:

- Screening. The primary stage of water treatment, during which wastewater passes through screens that retain fibers and insoluble impurities.

- Sedimentation — removal of suspended solids from wastewater. The method is based on gravitational forces, causing contaminants to settle at the bottom of sedimentation tanks.

- Filtration — separation of suspended solids by passing wastewater through fine-mesh screens or porous media such as anthracite, quartz sand, gravel, or similar materials.

- Centrifugation in hydrocyclones — separation of solid particles within a rotating flow of the medium.

After mechanical water treatment, sludge dewatering is performed. This process also consists of several stages:

- Preparatory stage. Preliminary dewatering of wastewater sludge is carried out using filter presses through conditioning by organic flocculation — aggregation of sludge using flocculants. This increases the sludge’s ability to release water.

- Main stage. The partially dewatered sludge layer obtained after the previous stage is covered with quicklime and converted into granules. During the reaction, the temperature of the solidified particle layer rises to +80 °C, promoting both dewatering and disinfection of the sludge.

- Final stage — complete dewatering of wastewater sludge by mechanical воздействие on the solidified particle layer using centrifugal force, vacuum, or pressure.

Facilities for Mechanical Wastewater Treatment

The main structural elements of facilities for mechanical wastewater treatment include:

- screens;

- grit chambers;

- sedimentation tanks.

Using screens for wastewater treatment, large floating contaminants are removed from the flow. Screens may be movable or stationary and are installed at an angle of 65–75° to the horizontal. During operation, wastewater screens require regular cleaning to remove accumulated debris.

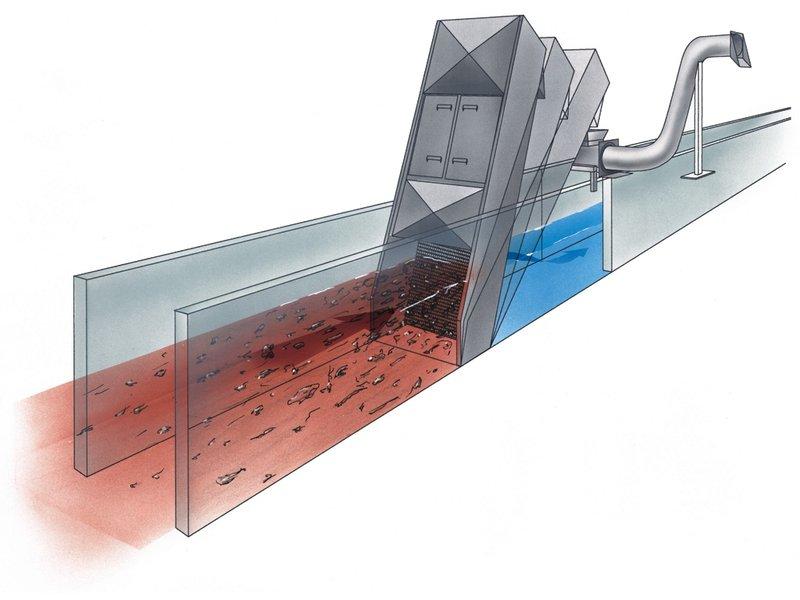

Grit chambers are designed to remove mineral contaminants from wastewater. The flow velocity through grit chambers must be adjusted so that only heavy mineral particles settle, while organic matter and finer particles are carried away by the water flow. Depending on the direction of wastewater movement, grit chambers are classified into three types:

- horizontal;

- vertical;

- slot-type — wastewater flows along the bottom of a special channel, where sand and impurities are separated.

Sedimentation tanks (grease traps) are reservoirs used for mechanical wastewater treatment in which contaminants are separated from a medium moving vertically or horizontally. Impurities may settle at the bottom of the tank or float to the water surface, depending on their physical properties.

Advantages of Mechanical Wastewater Treatment

Various mechanical wastewater treatment methods make it possible to remove the following from the effluent:

- large foreign objects;

- fats and oils floating on the wastewater surface;

- sand and other mineral particles.

A properly selected mechanical wastewater treatment method ensures effective preparation of the effluent for subsequent physical, chemical, or biological treatment.

The company offers cost-effective ready-made solutions for mechanical treatment of wastewater from industrial enterprises and sewerage systems. ZIKO specialists can visit the site, perform a detailed wastewater analysis, and recommend the most efficient water treatment equipment.

Detailed consultations regarding quality, technical characteristics, capacity, and cost of mechanical wastewater treatment equipment are available by phone using the number provided in the “Contacts” section. Requests for system design, development, equipment supply, and installation are also accepted via the company’s email address.