Underground Modular Tanks

The company “ZIKO” is an authorized representative of leading European manufacturers of above-ground and underground modular tanks.

Advantages of working with us:

- Wide range of dimensions

- 5-year manufacturer’s warranty

- Up to 50 years of service life

Above-ground modular tank capacity:

– from 18 to 500 m³

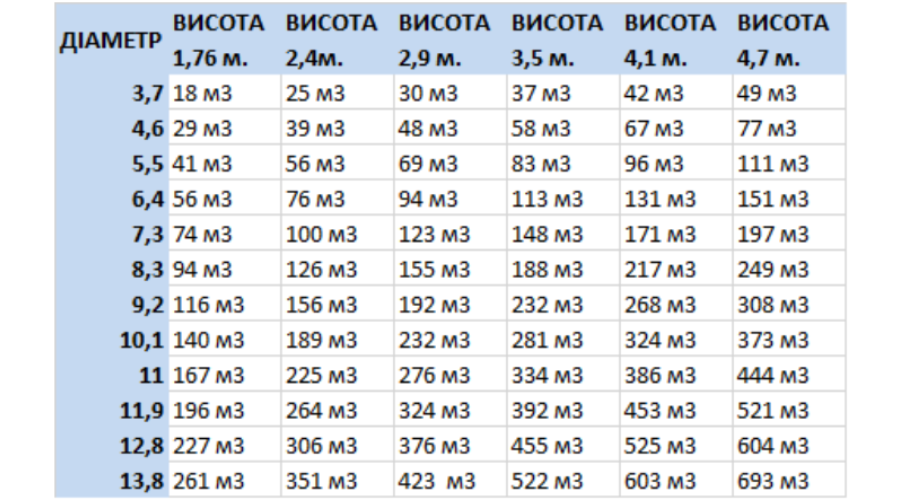

Underground tank dimensions:

- Height: from 1.8 to 4.7 meters

- Diameter: from 3.7 to 13.8 meters

The key advantage of these tanks lies in their underground installation and insulated roof design, which prevents liquids inside the tanks from freezing. As a result, no additional insulation or heating systems are required, eliminating extra operational costs. This allows year-round operation of underground tanks.

Areas of application:

- Drinking and technical water

- Firefighting water reserves

- Food product storage

- Wastewater storage

- Other mildly aggressive liquids

Underground tank dimensions

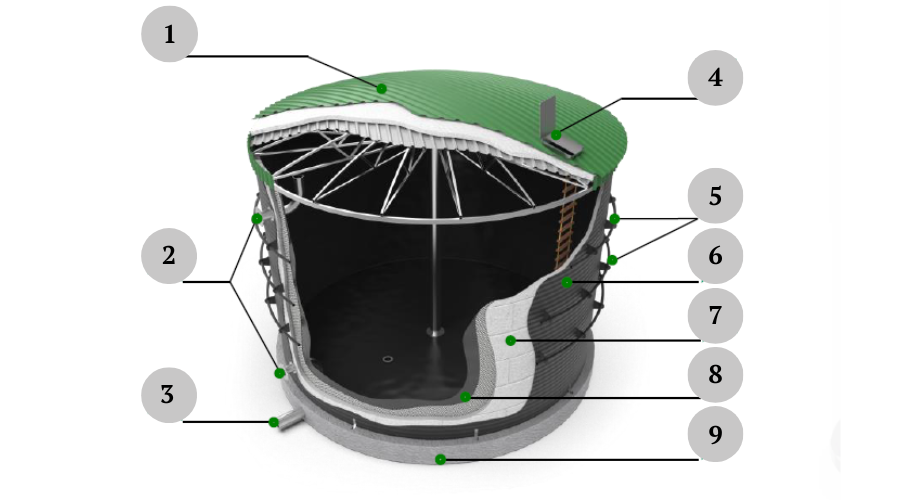

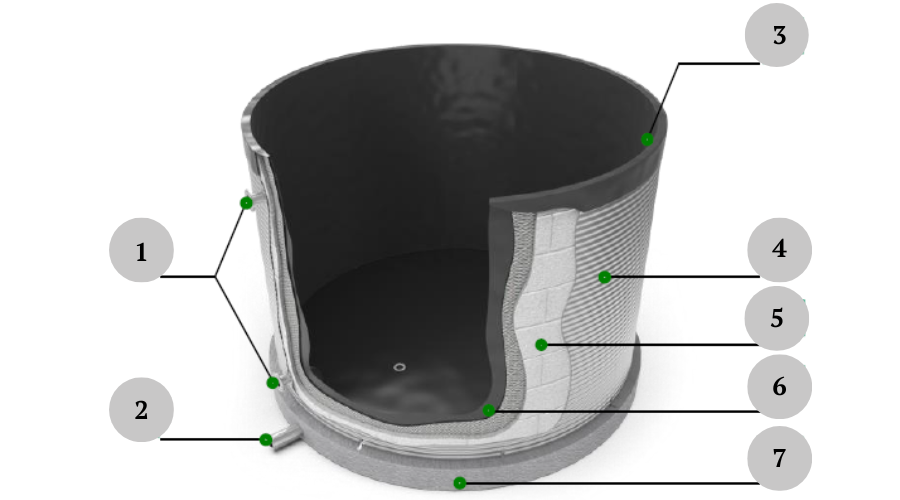

Diagram of an underground tank with a metal roof

- Metal roof (with insulation)

- Steel flanges for pipe connections (upon request)

- Bottom drain (upon request)

- Service hatch (500 × 500 mm)

- Stiffening rings

- Metal sheets with bitumen waterproofing, forming part of the structural frame

- Tank insulation (upon request)

- Liner (polypropylene membrane)

- Concrete foundation

We guarantee customized tank selection tailored to your requirements, as well as professional installation and maintenance services.

- Published in Модульні ємності – рішення

Above-Ground Modular Tanks

The company “ZIKO” is a representative of leading European manufacturers of above-ground and underground modular tanks.

Advantages of working with us:

- wide range of dimensions

- 5 years – manufacturer’s warranty

- 50 years – service life

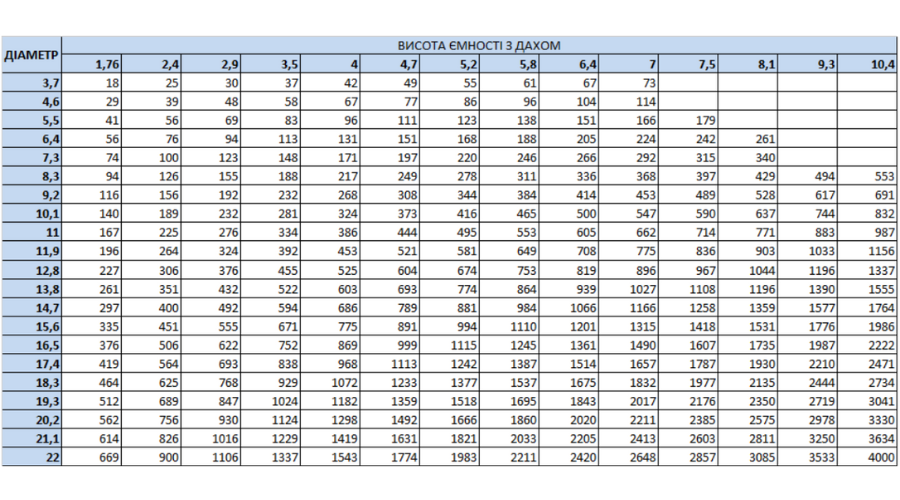

Above-ground modular tank capacity – from 25 to 4,200 m³.

Above-ground tank dimensions: tank height – from 1.8 to 22 meters, diameter – from 3.7 to 10.4 meters.

The main advantage of such tanks lies in the fact that due to above-ground installation there is no need for excavation, which ensures fast installation with minimal construction work. The tank is easy to transport, bring indoors for storage, and assemble.

Areas of application: storage of drinking water, technical water, fire water reserves, food products, UAN, wastewater, and other mildly aggressive substances.

Above-ground tank dimensions

Diagram of an above-ground tank with a metal roof

- Metal roof (or plastic)

- Steel flanges for pipe connection (upon request)

- Bottom drain (upon request)

- Service hatch (500 × 500 mm)

- Metal ladder (upon request)

- Metal sheets, forming part of the structural frame

- Tank insulation (upon request)

- Liner (polypropylene membrane)

- Concrete foundation

Diagram of an above-ground tank with a plastic roof

- Steel flanges for pipe connection (upon request)

- Bottom drain (upon request)

- Plastic tension roof or without roof

- Metal sheets, forming part of the structural frame

- Tank insulation (upon request)

- Liner (polypropylene membrane)

- Concrete foundation

We guarantee individual tank selection according to your needs, as well as professional installation and maintenance.

- Published in Модульні ємності – рішення

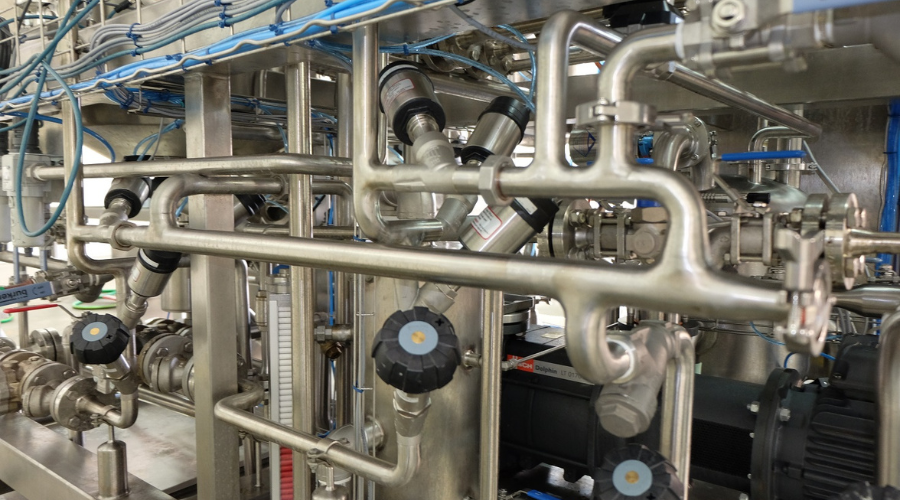

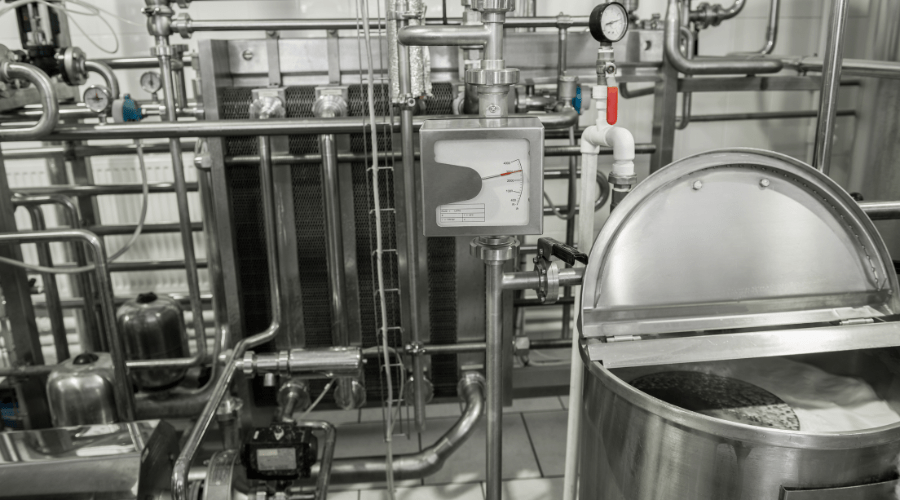

Water Treatment Systems for the Brater Brewery

Beer is an aqueous solution of extractive substances from malt that have not been transformed during fermentation, ethyl alcohol, and flavor and aroma compounds. Water is the main component of beer (accounting for at least 90% of any beer style), which makes it a determining factor in shaping the flavor characteristics of the final product.

Brewers often do not pay sufficient attention to the composition of the water used for brewing. However, the Bavarians — who remain trendsetters in brewing to this day — have long recognized that water quality plays a crucial role both in brewing technology and in the taste of the final product. The influence of water on beer flavor explains the historical regional characteristics of different beer styles, as the distinctive properties of certain types of beer are directly linked to the ionic composition of the water.

The water used for beverage production must first and foremost comply with drinking water standards. However, considering its impact on physicochemical and biochemical processes in brewing, additional requirements apply depending on the beer style and the manufacturer. These additional requirements for water used directly in beer production relate to parameters such as pH value, hardness, and the ratio between calcium (Ca²⁺) and magnesium (Mg²⁺) ion concentrations, which is not regulated for drinking water.

The manufacturer LLC “VZ GROUP”, trademark “Brater”, produces bottom-fermented beer (Lager). At the request of Czech brewing specialists and in compliance with water quality standards, the production facility was located in the suburb of Lviv, Kozhychi village, Yavoriv district, primarily due to the availability of a water supply with high-quality water (free from chlorine and other undesirable compounds).

The water source, discovered during the Austro-Hungarian period in 1898, is located in Volia-Dobrostanska village, Yavoriv district. Water quality has been tested and confirmed by an accredited laboratory. LLC “VZ GROUP” built the production facility from scratch, uses high-quality Czech equipment, and employs qualified technologists, which allows achieving an ideal flavor profile for its product.

The manufacturer approached the engineering company ZIKO with the objective of softening the water used in the production of light beer with a characteristic foam — Brater. During beer brewing, water must contain a specific amount of hardness salts, but only calcium-based salts, as magnesium salts cause beer bitterness and result in a darker wort color.

Traditionally, to determine the appropriate water treatment technology, specialists analyzed the quality of the source water through laboratory testing, based on which the following solution was proposed:

- Mandatory removal of mechanical impurities is implemented prior to the water softening system.

- After mechanical filtration, the water softening system comes into operation. It is easy to operate, consists of simple but reliable components, requires no additional attention, and ensures soft water. The system consists of four functional elements:

- filter media — sodium-form ion-exchange resin;

- control valve with a high safety margin;

- pressure vessel for media loading;

- brine tank that stores a reserve of tablet salt and water, the system of which prevents overfilling of the tank and air ingress into the system.

Specialists of the company ZIKO design water treatment and water preparation systems for use in brewing. At the same time, excellent results are guaranteed — the water will comply with all internal requirements and regulatory standards. We also focus not only on ensuring a reliable technological process, but also on reducing costs associated with water treatment, water preparation, and equipment maintenance.

Our specialists will be happy to answer any questions related to water treatment and water preparation. Simply call us or send an inquiry by email.

- Published in Побутове знезараження води – рішення, Рішення

Homogenization of Dairy Products

The company ZIKO is a representative of leading European manufacturers of homogenizers.

It is widely known that the main raw material at dairy enterprises is milk. As a result of established technologies and a number of technological processes, cheese, fermented dairy products, butter, and other products are produced. Milk is a valuable natural raw material whose composition has long been and continues to be the subject of extensive research. Most often, milk has been analyzed and described from the perspective of its impact on the human body and physiology. However, when focusing on the technical properties of milk, it acquires completely different characteristics. Knowledge of these properties is equally important both for production technology and for proper nutrition of adults and children.

So, what is milk? It is nothing more than an emulsion. An emulsion is a system of two or more immiscible liquids. From a thermodynamic point of view, it is an unstable system that tends to separate. One of the liquids forming the system is the dispersion phase (the solvent), while the other is the dispersed phase. In the case of milk, the dispersed phase is fat.

The homogenization process is a widely used method for reducing particle size in liquid and semi-liquid food products. As a result, homogenization increases the number of dispersed particles. The entire process occurs due to the action of shear forces, which significantly increase the stability of a dispersion system composed of two immiscible substances. Homogenization aims to fragment larger fat globules into smaller ones — down to 2 μm — in order to eliminate creaming, i.e., fat separation in milk. The homogenization process is typically carried out at a temperature of 70–75°C.

There are generally four main types of homogenizers.

The first type includes high-speed mixers — mixers equipped with high-speed turbines or propeller-type agitators, used for initial emulsification of low-viscosity liquids.

The second type is pressure homogenizers, in which piston pumps force liquid products under high pressure (approximately 10–70 MPa) through a narrow calibrated gap of about 0.3 mm at very high speeds, reaching several thousand meters per second. When used for milk, these devices reduce the size of fat globules to below 1 μm.

The third type includes colloid mills. These are primarily disc grinding machines of various designs, in which a small gap (0.05–1.3 mm) is formed between a vertical rotating disc (operating at 3,000 to 15,000 rpm) and a stationary disc, or between two counter-rotating discs, generating very high shear forces. These mills are particularly useful for homogenizing high-viscosity liquids.

The fourth type is ultrasonic homogenizers, in which high-frequency mechanical waves in the range of 18–30 kHz are generated by a vibrating plate. These waves cause cyclic stresses and cavitation in liquids with relatively low viscosity, resulting in emulsions with droplet sizes of approximately 1–2 μm. This type of homogenizer is used in the production of ice cream, fat emulsions, sauces, and for dispersing powders in liquids.

In essence, homogenization produces a uniform and stable mixture of substances that do not normally mix. The structural stability of the homogenized system is increased, and the effect of the process is most often associated with parameters such as the homogenization valve gap size, applied homogenization pressure, and the temperature of the homogenized medium.

During fluid flow and changes in cross-sectional area, both fluid velocity and static pressure change rapidly, resulting in deformation and complete breakup of fat globules. Under such flow conditions, cavitation and fragmentation of fat globules occur. The most important parameter affecting homogenization efficiency is pressure, the increase of which positively influences the homogenization effect. However, higher pressure requires larger equipment size, the use of high-strength materials, and robust sealing systems, impacting overall equipment dimensions, energy consumption, and operational durability.

It should also be noted that increasing pressure reduces particle size only up to a certain limit. This is because temperature is also a critical parameter, alongside pressure, influencing the homogenization process. Temperature affects fat globule dispersion, post-homogenization aggregation tendencies, milk color, and protein stabilization. According to available data, milk supplied to the homogenizer should have a temperature between 45°C and 65°C. Fat content is also important — higher fat concentration reduces homogenization efficiency.

From a technical standpoint, there is also a relationship between the length of the homogenization gap and homogenization pressure that determines the expected process outcome, taking into account the concentration of the fat phase in the product.

It is also necessary to select appropriate methods for evaluating the homogenization process in order to reliably and rationally assess its effectiveness. One of the main indicators of homogenization efficiency is the average diameter of fat globules, which closely correlates with homogenization pressure. Typically, the percentage ratio of fat globules of a specific size to the total number of dispersed particles is analyzed. Two primary methods are used to assess homogenization efficiency: microscopic and sedimentation methods.

The microscopic method involves measuring fat globule size by placing a liquid sample on a microscope slide and determining globule size using a micrometer. In each field of view, the total number of fat globules and the number exceeding 2 μm in diameter are counted. The result is calculated by subtracting the percentage of globules larger than 2 μm from the total number of globules.

The sedimentation method is based on milk’s tendency to separate fat from the aqueous phase, which is undesirable in industrial production. Evaluation is performed by placing 250 ml milk samples into Snellen cylinders and storing them in a refrigerator at 5–10°C for 2–3 days, depending on the adopted standard (American or Danish). After this period, fat content is measured in the upper and lower sections of the sample. Homogenization is considered effective if the calculated homogenization efficiency (ratio of fat content in the upper part to the lower part) is ≥ 90%.

Homogenization is widely used in the food industry for the production of milk, dairy products, juices, and baby food. Its advantages include improved structural stability, increased emulsion stability, and prevention of quality deterioration phenomena such as bitterness or phase separation. Milk meets the definition of an emulsion, as fat droplets are dispersed in an aqueous solution containing sodium, calcium, and potassium salts, with casein acting as an emulsifier.

From a physiological perspective, the emulsion form of milk enhances fat digestibility in the human body and helps maintain acid–base balance. Milk destined for packaging undergoes several technological operations: purification, fat standardization, homogenization, heat treatment (pasteurization or sterilization), filling, storage, and distribution.

Industrial homogenizers, unlike laboratory units, operate at much larger scales and are designed to meet the production capacity requirements of dairy plants. Homogenizers consist of two main components: a piston pump, responsible for generating high pressure, and a homogenization valve, which disperses fat particles and reduces their size. The process is mechanical, repeatable, and performed without oxygen access, ensuring high product quality and preventing undesirable reactions.

Homogenization can be single-stage or multi-stage (usually two-stage). Single-stage homogenization uses one homogenizing valve with a single pressure regulation system. Multi-stage homogenization can be achieved using multi-stage valves or multiple sequential valves with individual pressure regulation systems. Pressure can be adjusted mechanically or hydraulically, with gap height regulated by pressing the disc against the valve.

Manufacturers of homogenizers for dairy plants include Spomasz, OptiFlow, Hommak, Tetra Pak, and GEA Group, which offer solutions tailored to individual production needs. Their portfolios include homogenizers for small-scale laboratory use as well as large industrial applications.

For example, Spomasz offers homogenizers with capacities ranging from 300 l/h to 10,000 l/h, suitable for dairy processing. HM-type homogenizers can operate independently or in combination with pasteurizers and sterilizers, forming integrated pasteurization and homogenization lines. While homogenizers are generally energy-intensive and costly to maintain, modern developments focus on using more durable components and improving overall equipment design.

To receive consultation regarding technical specifications, equipment availability, and pricing, please submit a request via our website or contact us using the phone numbers listed in the Contacts section.

- Published in Технологічне обладнення – рішення

Vacuum Evaporator Units

The company ZIKO is a representative of leading European manufacturers of vacuum evaporator units.

Vacuum evaporation

The vacuum evaporation process involves reducing the internal pressure of the evaporation chamber below atmospheric pressure. This lowers the boiling temperature of the liquid being evaporated, thereby reducing or completely eliminating the need for heat in boiling and condensation processes. Lower heat demand has a positive impact on the energy efficiency of the process, resulting in cost savings and directly influencing the final product cost.

Practical use of vacuum evaporator units

Vacuum evaporator units are used in the food industry. Evaporation and removal of water from a product allow it to be stored for a significantly longer period. This process also reduces energy consumption during product processing, as the boiling temperature under reduced pressure is considerably lower than at atmospheric pressure.

Vacuum evaporator units are applied across many industrial sectors. Their popularity is determined by the versatility of the technology and its relatively low operating cost.

To receive a consultation regarding technical specifications, equipment availability, and pricing, please submit a request on our website or contact us by phone using the numbers listed in the Contacts section.

- Published in Технологічне обладнення – рішення

Autoclaves

The company ZIKO is a representative of leading European manufacturers of autoclaves.

Autoclaves are not only equipment used in laboratories or for sterilizing medical and cosmetic instruments. Various types of these machines are also widely used in industry, especially in the food industry. Below is an overview of how industrial autoclaves operate, their purpose, and areas of application.

How does an autoclave work and what is it?

Industrial autoclaves are sealed pressure vessels that allow thermal processing of products at temperatures exceeding 100 °C. As a rule, the main objective is to increase product shelf life and ensure storage safety. Due to the increased operating pressure of the autoclave (from 2 up to 6 bar), the heat transfer medium may be not only gas mixtures or steam, but also water.

Cylindrical vessels are manufactured from high-strength steel alloys, often acid-resistant, and are insulated using silicone or mineral wool. The walls are resistant to high temperature and pressure, and the unit is equipped with indicators for monitoring these parameters. In addition to the heating and cooling system, a critical component of the autoclave is the pressure relief valve, which safely regulates internal pressure.

Types of industrial autoclaves

Autoclaves can be classified according to various criteria, including design features such as vessel orientation (horizontal or vertical), the heating system used (electric, oil, or gas), intended application, or even the type of packaging of the processed product (for example, food autoclaves for jars). Our product range includes equipment with different specifications, including capacities from several hundred up to nearly two thousand liters.

From an industrial process perspective, it is also important whether the unit is designed for continuous or batch operation. Most often, industrial autoclaves are classified based on the heat transfer medium used:

- Steam autoclave — completely removes air from the chamber; steam is used as the heat transfer medium.

- Steam–air autoclave — the medium is a homogeneous mixture of air and steam, with independent control of temperature and pressure.

- Water cascade / spray / immersion autoclave — the medium is superheated water (the most popular type of food autoclaves).

To receive a consultation regarding technical specifications, equipment availability, and pricing, please submit a request via our website or contact us by phone using the numbers listed in the Contacts section.

- Published in Технологічне обладнення – рішення

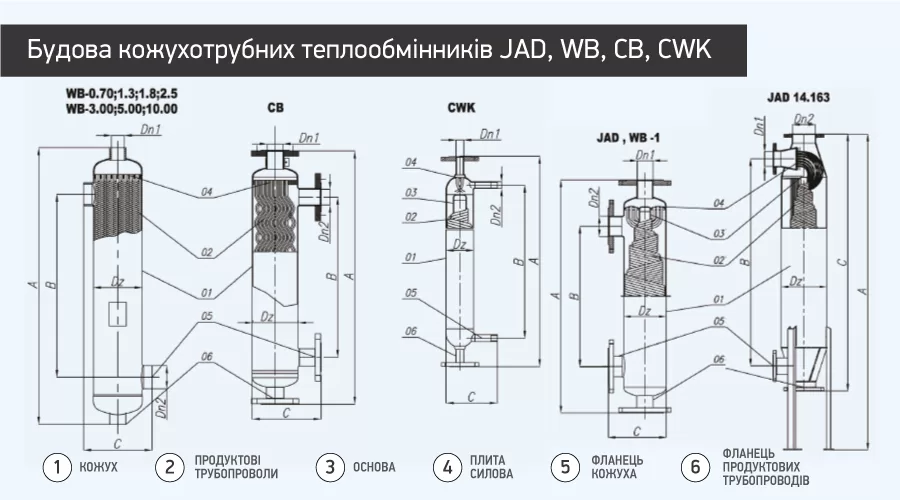

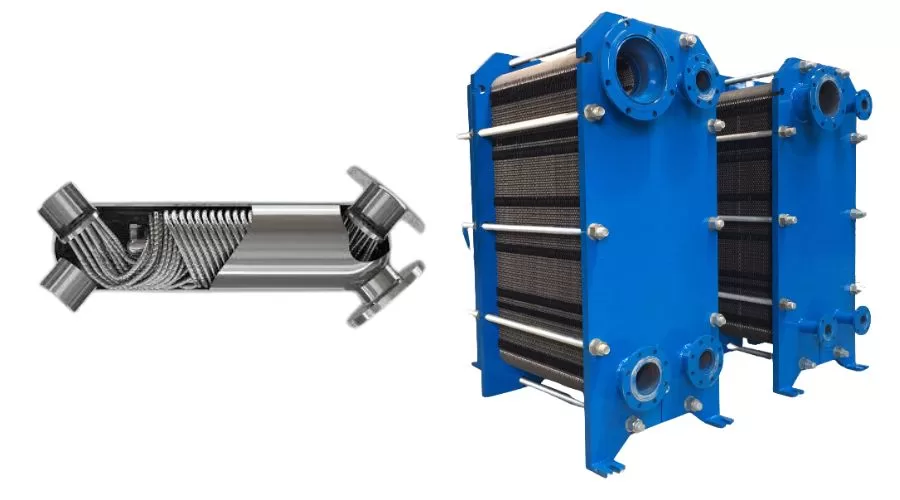

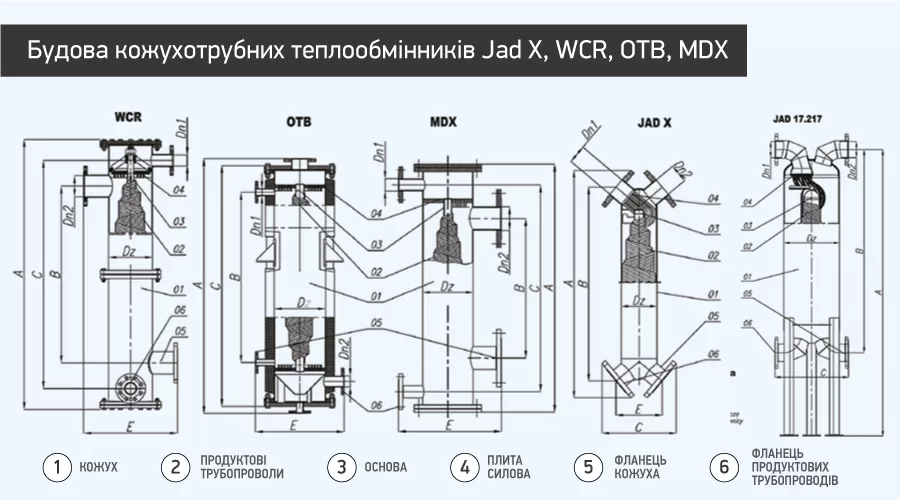

Heat Exchanger — Operating Principle

The company ZIKO is a representative of leading European manufacturers of heat exchangers.

Most food industry enterprises use heat exchangers in their production lines, which allow products to be quickly and efficiently cooled or heated. The operating principle of this equipment is not particularly complex and is usually designed in accordance with the individual requirements of a specific industrial installation.

So, what is a heat exchanger, how does it work, and what are its main types?

Heat exchangers are devices that enable heat transfer between specific media (liquids or gases). In modern industrial installations, pressurized steel heat exchangers of various designs are used, all based on a very similar operating principle. Their construction primarily depends on the method of heat transfer, which can be direct (contact) or indirect (non-contact). Heat exchangers are designed according to the specific installation and the working medium involved.

A heat exchanger provides heat transfer between fluids at different temperatures. Its operating principle is based on heat transfer by convection and conduction (heat exchange between liquids and gases). A high-temperature fluid releases thermal energy by convection to the wall or surface of a tube or plate. The heat then passes through the tube wall or plate and is ultimately absorbed by the colder fluid.

The exchange of thermal energy can occur, depending on the type of heat flow, by direct contact — when the media come into direct contact with each other — or by indirect (non-contact) transfer, when the media are separated from one another. In addition, the operating scheme of a heat exchanger may vary depending on the flow arrangement used in different systems.

Types of heat exchangers

By design, heat exchangers are classified as:

- shell-and-tube

- plate

- spiral

By type of heat transfer medium, exchangers are classified as:

- liquid-to-liquid

- liquid-to-gas

- gas-to-gas

We offer plate, tubular, and shell-and-tube heat exchangers of the JAD series manufactured by Spomasz Bełżyce S.A.

To receive a consultation regarding technical specifications, equipment availability, and pricing, please submit a request on our website or contact us by phone using the numbers listed in the Contacts section.

- Published in Технологічне обладнення – рішення

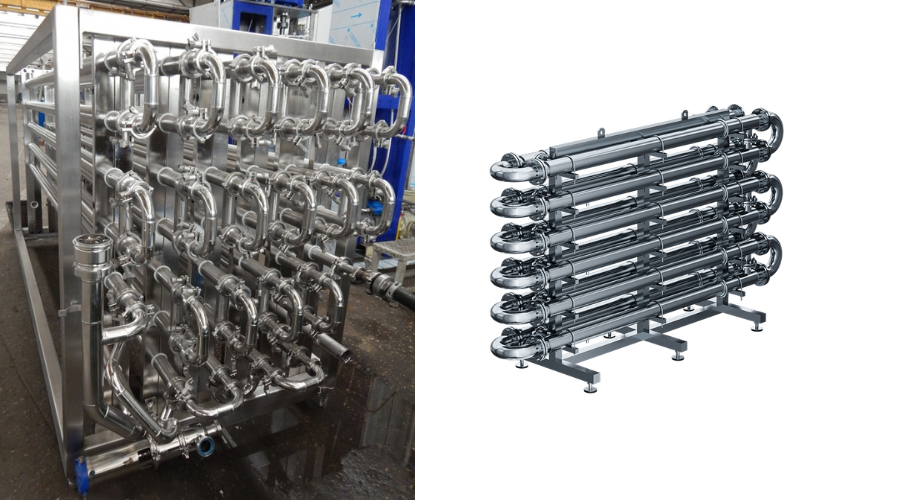

Pasteurization in the Dairy Industry

The company ZIKO is a representative of leading European manufacturers of pasteurizers and sterilizers.

Many factors have contributed to the development of the dairy industry as we know it today. Countless hours have been devoted to analyzing production processes and improving them. Many objectives would not have been achieved without human effort, dedication, and ingenuity. Often, at the very foundation lie techniques and technologies that passed their first successful laboratory tests as far back as two centuries ago. One of these is the technique known as milk pasteurization, without which it is difficult to imagine the modern food industry, including dairy production.

Milk pasteurization has been refined over time and adapted to increasingly large-scale food production. This led to the development of appropriate equipment — pasteurizers — designed to be installed on production lines for manufacturing essential food products such as milk and dairy products.

Milk pasteurization is a process aimed at eliminating microorganisms from the product, with particular emphasis on pathogenic forms that pose a threat to consumers. In food production, maintaining consumer health safety is critically important, especially in large-scale food distribution. The name of the process comes from its pioneer, Louis Pasteur, who lived in the 19th century. The researcher discovered the positive effect of thermal food treatment, which significantly extends shelf life.

Milk pasteurization is combined with other methods such as homogenization, membrane filtration, or centrifugation. In general, pasteurization is a food preservation process designed to destroy or inhibit the growth of pathogenic microorganisms and enzymes, while paying special attention to preserving the taste and nutritional value of products as unchanged as possible and preventing recontamination. During pasteurization, beneficial microorganisms are also destroyed.

In simple terms, milk pasteurization is the process of heating milk for a specific period of time. In general, two types of pasteurization can be distinguished: low-temperature pasteurization and high-temperature pasteurization. The differences between them are determined by variations in process parameters, namely time and temperature.

Low-temperature pasteurization of milk is also known as long-time pasteurization or LTLT pasteurization. LTLT (Low Temperature Long Time) pasteurization, as the name suggests, involves prolonged exposure to a relatively low temperature. In this case, thermal treatment lasts approximately 30 minutes at 63°C.

High-temperature milk pasteurization, also known as HTST (High Temperature Short Time) pasteurization, involves exposure to a higher temperature for a shorter period. The selection of process parameters in this case depends on the quality of raw milk. Typically, milk is heated to 72–75°C and held under these conditions for approximately 15–20 seconds.

In the case of cream pasteurization, which is subsequently used, for example, in butter production, pasteurizers are set to a temperature of approximately 92°C for 30–40 seconds. The change in parameters for this raw material is due to its high fat content. The protective role of fat lies in forming a specific water-free оболонка around microorganism cells, which complicates the pasteurization process and necessitates adjustments to its parameters.

Milk pasteurization ensures the destruction of heat-sensitive microorganisms, including yeasts, molds, and bacteria that do not form endospores. Microorganisms present in milk that may negatively affect human health can be characterized by parameters defining their thermal resistance. These parameters are specific to a given bacterial species and may vary depending on environmental conditions and within a given population.

The resistance of microorganisms to heat depends on the environment in which they are present. In milk, their thermal resistance is influenced by water activity, pH, fat content, and protein content. Milk is an aqueous medium for microorganisms, and the destructive effect of heat increases as the dry matter content decreases. The number of microorganisms that survive thermal destruction at a constant temperature follows a logarithmic relationship. According to literature data, this logarithmic nature of microbial inactivation leads to important conclusions applicable in laboratory practice: when the initial number of microorganisms in raw material is high, i.e. when milk has a high initial microbial load, the heating time at a constant temperature must be extended (the higher the temperature, the faster bacteria are destroyed) to achieve the required microbiological purity of the product, meaning the desired reduction in the number of microorganisms.

It is also important to note that it is impossible to destroy all cells completely, as this would require infinite heating time. Therefore, the effectiveness of milk pasteurization is generally estimated at approximately 99%. The presence of microorganisms in milk poses a risk to consumer health, which is why pasteurization aims to eliminate as many of them as possible. Consequently, it is crucial to determine the success of pasteurization and confirm its effectiveness.

So, how can we prove that the pasteurization process for milk and dairy products has been carried out correctly? The effectiveness of pasteurization in the finished product is confirmed by determining the activity of a naturally occurring milk enzyme — alkaline phosphatase (ALP). This enzyme is inactivated at high temperatures.

According to current regulatory requirements, the activity of ALP in pasteurized cow’s milk is limited and must not exceed 350 mU/l. Alkaline phosphatase is not the only enzyme sensitive to high temperatures. Research has shown that gamma-glutamyl transferase and lactoperoxidase are also reliable indicators of pasteurization efficiency and proper thermal treatment conditions for milk and dairy products. This is because the thermal resistance of these enzymes is higher than that of most non-spore-forming microorganisms found in milk.

Alkaline phosphatase activity depends, among other factors, on the fat content of milk, the cattle breed, and the type of feed used. As mentioned earlier, the presence of ALP in milk after pasteurization indicates insufficient process quality. The amount of ALP remaining after pasteurization is referred to as residual phosphatase, and testing for ALP activity has become a standard method for monitoring pasteurization effectiveness.

ALP activity can be determined using classical colorimetric methods, as well as instrumental analyses based on radiation measurements, such as chemiluminescence or fluorometric analysis, or tests based on electrochemical reactions, including amperometric and potentiometric methods, as well as rapid test strips. However, rapid test strips do not allow for quantitative determination of the enzyme.

In the dairy industry, it is extremely important to control thermal processing conditions, as they often represent a critical control point in the production of finished products. Today, in modern dairy processing plants, pasteurization is carried out as part of an integrated technological line alongside processes such as homogenization and centrifugation.

Milk pasteurization is carried out in devices called pasteurizers. Milk is transported through pipelines into the pasteurizer after the pumps are started. Pasteurizers can operate in batch or continuous mode. A prerequisite for heat flow is the occurrence of a temperature gradient — heat is transferred from a fluid with a higher temperature to a fluid with a lower temperature.

The most commonly used heat exchanger in the dairy industry is the plate pasteurizer. This solution involves mounting a series of plates arranged in parallel on a supporting frame. The heating medium is hot water. The pasteurized product — milk — flows in so-called counter-current flow relative to the heating medium. This solution ensures more efficient heat exchange between fluids. The liquids move through channel spaces formed between the plates, which separate the heating medium from the pasteurized liquid.

Modern solutions provide for dividing the plates of the heat exchanger into sections, each of which performs a specific function within the overall pasteurization process.

The following sections can be distinguished:

- a section where water is heated by steam;

- a milk pasteurization section, where the core of the process takes place — heating milk with hot water from the previous section to the pasteurization temperature;

- a holding section consisting of plates with deep channels, where milk heated to the pasteurization temperature is held at this temperature for a specified time of 15 to 30 seconds;

- a heat regeneration section consisting of two or three sections, in which cold milk entering the pasteurizer is preheated by heat recovered from hot milk leaving the holding section.

In addition, there is a two-section cooling stage for further cooling of pasteurized milk, first with cold water and then with ice water.

Plate heat exchangers offer a number of advantages. The most important include: a high level of heat recovery in the regeneration section — reaching 80–90%, which results in significant energy savings; the ability to control system efficiency by adjusting the number of plates in individual sections; ease of operation; ease of cleaning; and the ability to pasteurize, in addition to milk, many other liquid and semi-liquid products, such as cream. The use of a holding section is optional, and partial milk degassing is also possible. Modern plate pasteurizers available on the market are equipped with design elements that maintain the set pasteurization temperature and systems that automatically divert milk if it has not been sufficiently pasteurized.

The compact design of plate heat exchangers means they require relatively little installation space. The plates are thin, metal, and corrosion-resistant. They are joined together either by brazing or using a tightening frame. The plates are arranged in such a configuration that openings in their upper and lower corners form flow channels. Flow control within the channels is achieved using gaskets around the openings, separating the flows from one another. The hot medium flows on one side of the plate, while the cold medium flows on the other. Heat exchange between the fluids occurs without direct contact, with both fluids flowing in counter-current arrangement.

The surfaces of heat exchanger plates are embossed with various patterns. This increases flow turbulence for both fluids at relatively low flow velocities during milk pasteurization. Increased turbulence improves heat transfer coefficients and reduces the formation of deposits from the liquid. Turbulent flow supports heat diffusion and prevents the formation of temperature layers characteristic of laminar flow. Heat transfer coefficients in plate heat exchangers can be up to twice as high as those in shell-and-tube exchangers.

The counter-current flow system can be series, parallel, or mixed. These design concepts aim to direct the flow on both sides of the plates so that the fluids undergo multiple changes in flow direction. In a series configuration, the flow path is long, resulting in high hydraulic resistance at relatively low flow velocity. In a parallel system, the flow path is short — equal to the length of a single channel — resulting in a low pressure drop.

To combine the advantages of both solutions, mixed systems are used. In such systems, the desired flow velocity is achieved through plates with parallel channels, while plates with series channels ensure the required temperature change of the media in both circuits.

Plate heat exchangers must be cleaned in accordance with manufacturer recommendations and using approved cleaning agents to avoid undesirable side effects, such as microscopic surface damage to the plates that is not visible to the naked eye.

To ensure optimal control of thermal food preservation, modern dairy plants use computer-based pasteurization process control, consisting of properly programmed controllers. Dedicated software monitors all parameters related to correct process execution, enabling full control over the technological process and line operation. If critical values are exceeded, the system triggers an alarm and initiates procedures to prevent further production of defective product. Milk that does not meet specified parameters can be redirected for re-pasteurization. Automated line control with process visualization not only simplifies operation but also enables analysis of archived process data, which can be useful for production planning and reporting.

Within automated supervision of the pasteurization line, the controller is responsible, among other tasks, for: controlling pumps and valves; monitoring, recording, and regulating pasteurization temperature; controlling outlet product temperature; monitoring outlet pressure; and storing and archiving operating modes and parameters on a computer disk. Visualization of line operation using graphical and textual elements facilitates real-time process monitoring and parameter analysis.

The market offers a wide range of heat exchangers from manufacturers and suppliers such as Spomasz Bełżyce, Alfa Laval, GEA, Sondex, and Tetra Pak. Physical properties of the fluid — such as viscosity, density, and specific heat capacity — affect heat exchanger efficiency and configuration, and thus determine the selection of the most suitable device. To correctly select a heat exchanger, a number of parameters must be defined, including: type and properties of the medium, inlet and outlet temperatures, flow velocity and volume, minimum, maximum, and operating pressure, allowable pressure drop, resistance related to deposits, as well as financial considerations.

Many companies offer support in selecting a heat exchanger that will perform optimally under given process conditions and be properly sized for the application. The range of possible design configurations is extensive, making it possible to adapt equipment to virtually any operating conditions. The key priority remains ensuring process repeatability and microbiological safety, which are critical in food production.

For consultation regarding technical specifications, equipment availability, and pricing, please submit a request on our website or contact us by phone using the numbers listed in the Contacts section.

- Published in Технологічне обладнення – рішення

What is Sludge Dewatering, Its Applications and Advantages

During the wastewater treatment process, sludge is generated. Sludge is a residual semi-liquid material with a moisture content of approximately 98%.

Sludge has long been a serious challenge for the water treatment industry, as it increases environmental risks and significantly raises disposal costs when handled in liquid form. Sludge dewatering is the process of reducing waste volume to enable efficient disposal. Dewatering separates sludge into solid and liquid fractions, thereby minimizing waste.

Depending on the viscosity of the sludge, required capacity, and available budget, several different sludge dewatering methods are used.

Belt filter

Belt filters are among the less intensive sludge dewatering methods, based on gravitational dewatering. This results in a higher water content in the final product, but such systems are often more cost-effective. An alternative is the belt vacuum filter, which accelerates the dewatering process.

Belt filters use filter belts that transport sludge through several stages, allowing water to drain from the sludge under the influence of gravity or vacuum. This process is repeated 2–3 times until primarily the solid fraction remains.

Centrifuge

Centrifuges provide a higher degree of separation compared to belt presses, producing solid sludge with a lower moisture content. They require little installation space but may involve higher capital costs.

A centrifuge operates by rotating a cylindrical bowl containing sludge. As the bowl spins at high speed, centrifugal force separates water and solid particles based on density. This results in two separate streams: treated wastewater, which is returned for further processing, and solid material, which is disposed of.

Chamber (plate-and-frame) filter press

Chamber filter presses are available in high-pressure and low-pressure versions. High-pressure systems can achieve lower moisture content, as higher pressure inside the chambers allows for greater solid accumulation from the sludge.

A chamber filter press operates by simultaneously filling multiple chambers. These chambers are separated by filter plates, which divide the sludge into water and solid fractions.

Sludge dewatering processes

Before dewatering, sludge is conditioned using organic chemicals such as flocculants and coagulants, or mineral chemicals such as iron salts and lime.

After conditioning, the sludge is thickened, often using a screw drum. Thickening processes concentrate the sludge by removing part of the water, thereby increasing the content of dry solids. During thickening and dewatering, two products are formed:

- solid sludge, which is transported to sludge storage or disposal sites;

- process water, which is returned to the beginning of the treatment plant.

Advantages of sludge dewatering

Environmentally friendly

Sludge dewatering is an environmentally safe process regulated by legislation. All wastewater treatment plants must be equipped with liquid sludge dewatering systems. The process significantly reduces the volume of waste requiring disposal.

Reduced transportation costs

Sludge disposal is a costly process. Dewatering equipment reduces expenses related to sludge storage and transportation.

Lower risk of spills and leaks

Consistently dry sludge reduces the risk of spills or leaks during transport. Spillage is a major concern for truck operators, whereas dry sludge cakes with high solids content significantly minimize this risk.

Reduced waste volume

Sludge dewatering reduces both the volume and weight of waste prior to disposal, leading to lower disposal costs.

Easy automation

Although sludge dewatering equipment is sometimes considered labor-intensive, it is, in fact, easily automated. For example, sludge presses can be equipped with advanced control systems, automatic belt washing units, and mechanical sludge discharge systems, ensuring continuous operation and seamless integration with the plant’s main control system.

Conclusions

Sludge dewatering is primarily aimed at waste minimization, reducing both sludge volume and weight. This contributes to overall cost efficiency, particularly by lowering disposal and transportation costs.

In addition, stabilized sludge can be reused, handled more safely, and poses a lower health risk. Both private and public sectors are generally required to dispose of sludge in ways approved by regulatory authorities, in accordance with organizational requirements and environmental safety standards.

- Published in Промислові системи очищення стоків – рішення

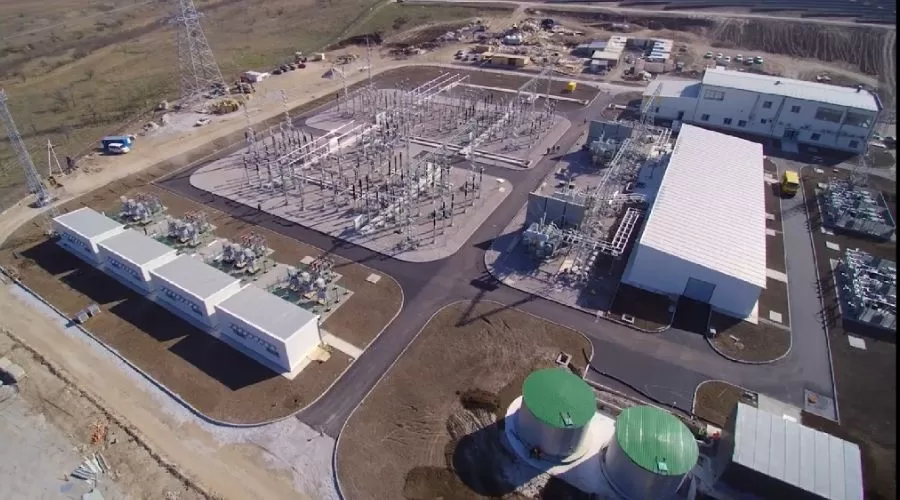

The company ZIKO offers ready-made modular metal-plastic tanks for the storage of mildly aggressive substances, UAN (urea–ammonium nitrate solutions), molasses, oil, as well as technical and drinking water.

We also design, manufacture, and install tanks individually, in various types and capacities, according to customer requirements. A 5-year quality warranty is provided for all manufacturing materials, finished structures, and installation services.

What modular metal-plastic tanks are and what they are used for

Quick-assembly modular metal-plastic tanks are specialized technological reservoirs designed for storing large volumes of various liquids — from ordinary water to mildly aggressive substances. Their frames are made of galvanized steel sheets, which ensures high mechanical strength. Inside, the structures are sealed with special polypropylene plastic membranes, providing full water tightness of the tanks.

Purpose of modular metal-plastic tanks

Quick-assembly modular tanks of various types and capacities are used:

- As drinking water reservoirs for water supply systems of cities, towns, and villages.

- For storing large volumes of drinking and technical water in agriculture and at industrial facilities.

- As tanks for safe and long-term storage of molasses and oil at enterprises engaged in sugar beet and sunflower processing.

- As water reservoirs in fire protection systems of industrial facilities, individual buildings, and structures.

- For large-volume storage of UAN (urea–ammonium nitrate solutions), other liquid mineral fertilizers, mildly aggressive substances, and acids.

Modular metal-plastic tanks are also widely used as basins for breeding and cultivating various species of fish, mussels, and crayfish.

Components of a modular tank structure

The structure of a modular tank consists of several elements that ensure structural strength, tightness of the tank, and protection of stored liquids from the negative effects of sunlight and precipitation:

- Concrete foundation, minimum thickness — 40 cm. It must extend 20–40 cm beyond the tank diameter. A strip foundation may also be used as the base.

- Frame. For small tanks with a capacity of up to 100 m³, flat metal sheets are used as the structural base. For larger tanks, galvanized corrugated steel sheets with a thickness of 1–4 mm are applied. This material offers high strength and excellent corrosion resistance, significantly reinforcing the structure and extending its service life.

- Sealing tank membrane made of black polypropylene. This is a UV-stabilized material with a thickness of 0.6–0.75 mm, certified for the storage of food products and drinking water.

- Piping connections — galvanized threaded pipes with nuts, diameter 32–250 mm.

- Roof. Can be manufactured from two materials: galvanized metal or plastic (polypropylene or PVC).

- Configuration options: equipment for filling, draining, and transferring liquids. Additional components may include ladders, level sensors, measuring scales, pumps, ventilation nozzles, valves, floats, and other accessories.

If, during operation of a modular metal-plastic tank, it is necessary to minimize heat loss, the tank can be thermally insulated and equipped with liquid heating systems for winter operation.

Types of modular tanks

Depending on design features, configuration, and purpose, the modular tanks offered by our company can be divided into four types:

- Above-ground tanks without a roof. Intended for seasonal outdoor use or indoor installation.

- Above-ground tanks with a plastic roof. Also designed for indoor operation or seasonal outdoor use.

- Above-ground tanks with a metal roof, suitable for year-round outdoor operation.

- Underground tanks with a metal roof and insulation, primarily intended for storing large volumes of water in firefighting systems.

Advantages of modular metal-plastic tanks

The main advantages of modular tanks are structural strength, practicality, and ease of operation. It is also worth highlighting the following benefits of our tanks:

• Long service life. All types of modular tanks are supplied with a 5-year quality warranty. The potential service life is 25 years or more.

• Affordable price. The cost of modular tanks offered by our company is 2–3 times lower than that of tanks with similar design and capacity from other manufacturers.

• High quality and durability of materials. The frames are made of high-quality galvanized steel, which ensures high structural strength, prevents corrosion-related damage, and extends the service life of the tanks. The membranes are made of polypropylene, a material certified for storing drinking water and food-grade liquids. The plastic is resistant to acids and mildly aggressive substances. The tanks can store water heated up to 110 °C.

• Ease of installation, dismantling, and transportation. The structures are assembled within 1 to 21 days (depending on capacity and configuration). They can be installed even in hard-to-access locations and indoors. The tanks are easy and quick to dismantle, take up little space when disassembled, and can be transported by standard freight vehicles without the use of special equipment.

• High structural strength. The tanks withstand high wind loads (up to 45 m/s) and remain intact during tornadoes, hurricanes, and earthquakes.

• Wide range of standard sizes (approximately 400 models) and capacities: from 18 m³ to 1,219 m³ for underground tanks and from 18 m³ to 4,177 m³ for above-ground tanks.

Modular metal-plastic tanks can be custom-equipped with various additional components. Depending on customer requirements and technological process needs, inlet, outlet, and drain openings of various diameters can be installed at any required location on the tank. The structures can be equipped with liquid level sensors, external ladders, and thermal insulation. Additionally, electric heating elements (heaters) for liquid heating and other equipment may be installed.

Areas of application of modular tanks:

• fire protection systems — for storing sufficient volumes of water required for firefighting;

• storage and distribution of UAN (urea–ammonium nitrate solutions);

• water supply systems for populated areas;

• storage of molasses and oil at industrial enterprises;

• tanks for accumulation and storage of large water reserves;

• wastewater and contaminated water treatment systems;

• basins for breeding and cultivation of fish, crayfish, and mussels.

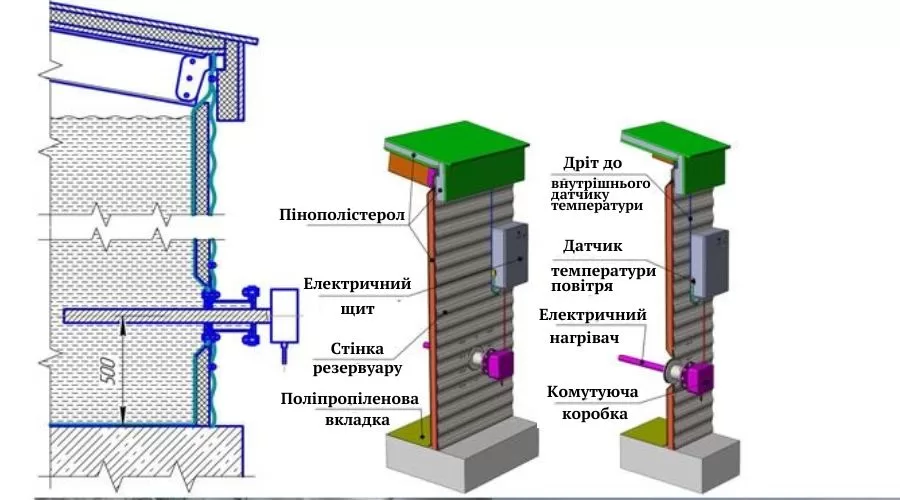

Thermal insulation and equipping tanks with liquid heating systems for winter operation

To reduce heat loss during winter operation, the tanks are thermally insulated and equipped with liquid heating systems. Mineral wool with a density of 80–110 kg/m³ and a thickness of 50–140 mm is glued to the galvanized frame from the inside. The insulation layer is covered with geotextile, after which the membrane is installed.

For liquid heating during the winter period, the tank is equipped with electric heating elements (heaters), temperature sensors, and an automatic control system. When the ambient temperature drops to +1 °C, the control system automatically activates the heaters. Once the water or other liquid reaches the set temperature, the sensors transmit information to the control system, which then switches off the heating elements.

Interested in our offer? Would you like to receive more information about the materials, technical characteristics, and applications of modular metal-plastic tanks?

Submit a consultation request via the feedback form on our website, call us, or send us a message. We will contact you in any convenient way and answer all your questions.

- Published in Баки та гідроакумулятори – рішення, Рішення