ZIKO supplies a wide range of industrial sewage pumping stations with delivery across Ukraine for various application areas. All equipment complies with current quality standards. The company also supplies water filters, reverse osmosis systems, and provides services for design, engineering, configuration, and installation of water treatment and water preparation systems.

Purpose of Sewage Pumping Stations

The main function of sewage pumping stations (SPS) is to lift wastewater using pumps to a level required for gravity discharge into a water body, receiving reservoir, or sewer system. Such equipment is used for pumping:

- stormwater runoff;

- drainage water;

- industrial, domestic, and utility wastewater.

High-capacity sewage pumping stations are indispensable when wastewater must be transported across elevated terrain.

Types of Sewage Pumping Stations

Depending on installation and design features, industrial water pumps and sewage pumping stations are divided into three main types:

- Vertical stations. These units are most often manufactured from fiberglass and are equipped with two pumps operating alternately. Fiberglass SPS units are resistant to aggressive chemical environments. A vertical sewage pumping station may also be equipped with solid filtration devices, ventilation systems, and autonomous control systems.

- Horizontal stations. An industrial horizontal sewage pumping station operates on the same principle as a vertical unit but is equipped with submersible pumps and automatic liquid level monitoring systems.

- Stations with self-priming pumps. The housing of such a sewage pumping station has a cylindrical shape and is divided into two sealed compartments: a wet chamber and a dry chamber. The system is equipped with wastewater filtration devices, and the internal pump components include heating elements. This type of equipment is recommended for use in low-temperature regions.

Reliable operation of a sewage pumping station depends on the correct selection of equipment. Therefore, before purchasing and installing an SPS, it is necessary to carefully evaluate equipment specifications, site conditions, and the requirements of technological processes.

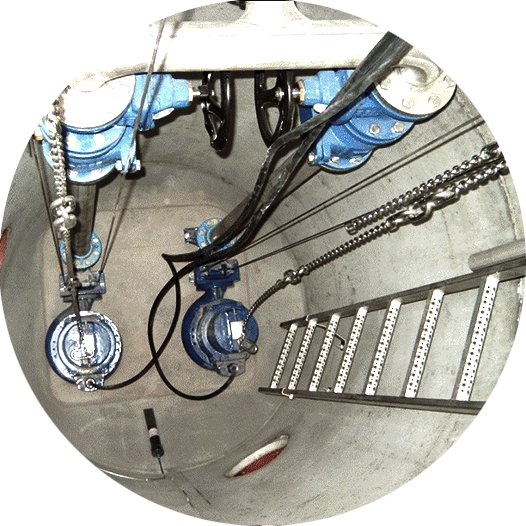

Standard configuration of a sewage pumping station includes:

- a durable housing with stiffening ribs made of stainless steel, fiberglass, plastic, or other corrosion-resistant materials;

- pumps for wastewater transfer;

- pressure pipelines;

- shut-off and auxiliary valves regulating liquid inflow;

- automation systems for operation control and liquid level monitoring.

Operating Principle of a Sewage Pumping Station

Wastewater flows through pipelines into the receiving tank of the sewage pumping station, where the pumps are installed. The pumps transfer the wastewater into a pressure pipeline, from which the medium is discharged into the sewer system.

The distribution chamber is equipped with gate valves and a check valve. The gate valves control the discharge of liquid into the pipeline. During normal operation, the valves remain open, while during maintenance or repair they are closed. The check valve prevents wastewater from flowing back into the system.

Advantages of Sewage Pumping Stations

The main advantage of sewage pumping stations is their ability to efficiently remove wastewater when gravity-based transportation to treatment facilities is not possible. Additional advantages include:

- use of high-quality polymer materials resistant to aggressive substances, ensuring reliable operation and long service life;

- complete configuration with equipment required for liquid transfer, including automation systems, shut-off valves, safety valves, and drainage pumps;

- compact design — a sewage pumping station occupies significantly less space than reinforced concrete wastewater storage tanks, allowing optimization of drainage system layouts;

- cost efficiency — automated control systems activate pumping equipment only when the tank reaches a preset filling level, reducing electricity consumption.

How to Choose a Sewage Pumping Station

First of all, sewage pumping stations differ in pump characteristics, including operating principle, design features, capacity, and power. Other important selection criteria include:

- composition of wastewater;

- location of the inlet collector;

- required pumping head and distance to the discharge point;

- volume of wastewater entering the system;

- project-specific requirements;

- terrain characteristics;

- type of pumping equipment and control method.

To select and purchase the most efficient sewage pumping station, an individual engineering calculation is required. This calculation should take into account the required configuration, dimensions, maximum and operating capacity of the unit.

Only specialists with appropriate qualifications and technical expertise can ensure compliance with all engineering and construction standards during installation. Therefore, for stable and uninterrupted operation, sewage pumping stations should be designed and installed by professionals.

More detailed information on configurations, technical characteristics, and pricing of the sewage pumping stations we offer is available by phone using the number provided in the “Contacts” section. ZIKO managers also provide consultations and accept equipment supply requests via email or through the feedback form on our website.