The company ZIKO is a representative of leading European manufacturers of heat exchangers.

Most food industry enterprises use heat exchangers in their production lines, which allow products to be quickly and efficiently cooled or heated. The operating principle of this equipment is not particularly complex and is usually designed in accordance with the individual requirements of a specific industrial installation.

So, what is a heat exchanger, how does it work, and what are its main types?

Heat exchangers are devices that enable heat transfer between specific media (liquids or gases). In modern industrial installations, pressurized steel heat exchangers of various designs are used, all based on a very similar operating principle. Their construction primarily depends on the method of heat transfer, which can be direct (contact) or indirect (non-contact). Heat exchangers are designed according to the specific installation and the working medium involved.

A heat exchanger provides heat transfer between fluids at different temperatures. Its operating principle is based on heat transfer by convection and conduction (heat exchange between liquids and gases). A high-temperature fluid releases thermal energy by convection to the wall or surface of a tube or plate. The heat then passes through the tube wall or plate and is ultimately absorbed by the colder fluid.

The exchange of thermal energy can occur, depending on the type of heat flow, by direct contact — when the media come into direct contact with each other — or by indirect (non-contact) transfer, when the media are separated from one another. In addition, the operating scheme of a heat exchanger may vary depending on the flow arrangement used in different systems.

Types of heat exchangers

By design, heat exchangers are classified as:

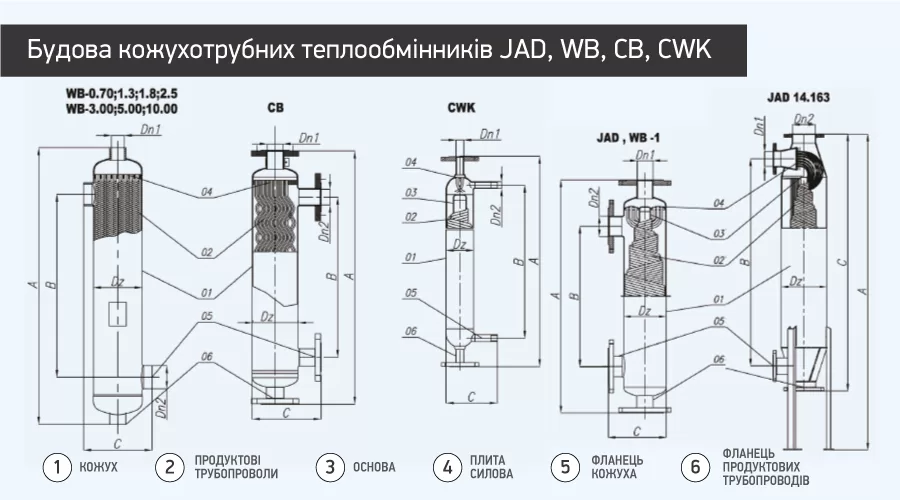

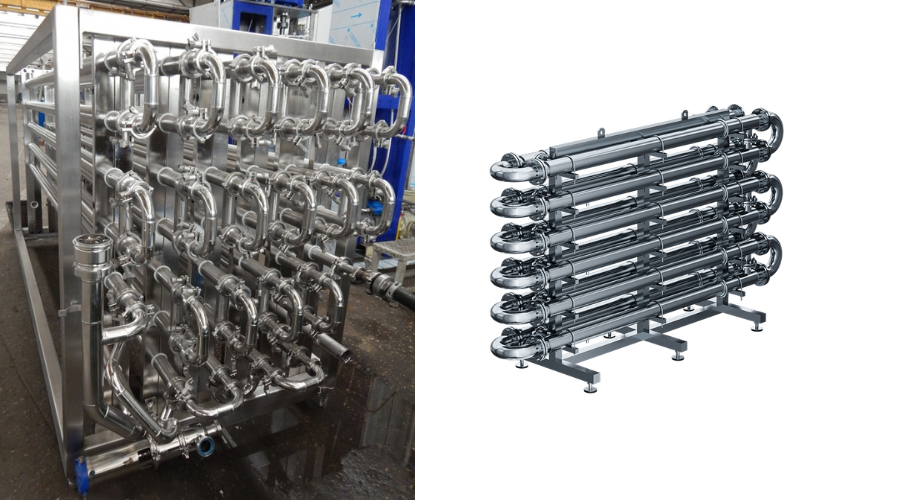

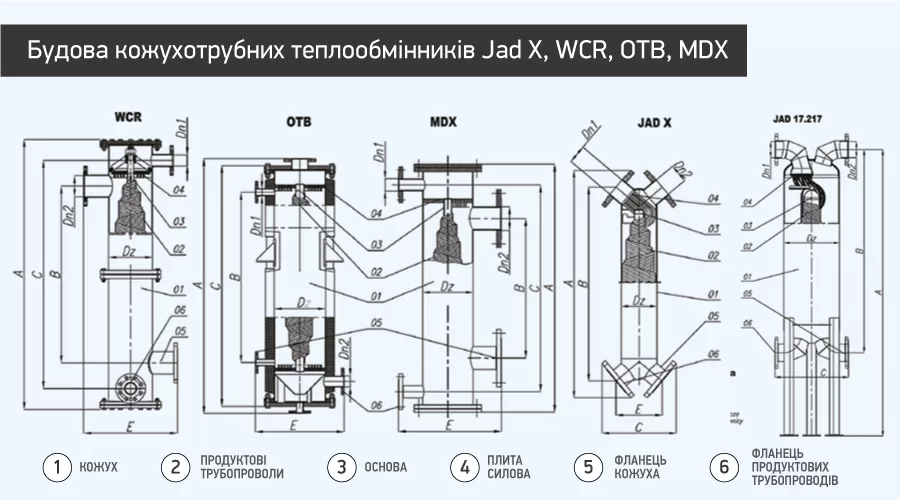

- shell-and-tube

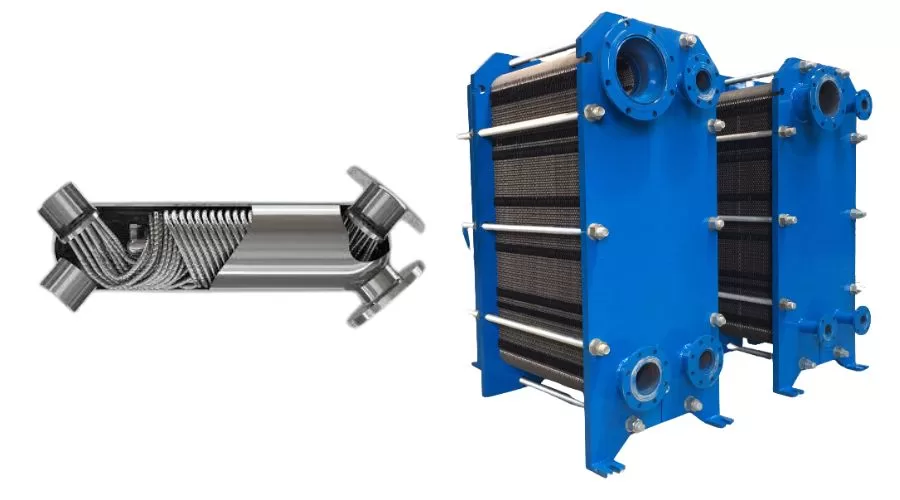

- plate

- spiral

By type of heat transfer medium, exchangers are classified as:

- liquid-to-liquid

- liquid-to-gas

- gas-to-gas

We offer plate, tubular, and shell-and-tube heat exchangers of the JAD series manufactured by Spomasz Bełżyce S.A.

To receive a consultation regarding technical specifications, equipment availability, and pricing, please submit a request on our website or contact us by phone using the numbers listed in the Contacts section.