AKO INDUSTRIES — MANUFACTURING OF METAL BUILDING STRUCTURES

New Challenges of Industrial Water Treatment in Ukraine

For more than 30 years, every day our Company has been approached by an increasing number of Customers with extremely complex and at the same time interesting challenges. We truly appreciate non-standard tasks, as this confirms that ZIKO is a leader in the Ukrainian market for water treatment solutions and beyond.

In this article, we would like to share our experience in implementing one of the more complex and interesting projects. The Customer, AKO Industries, is a global leader in drainage systems. The company’s management pays exceptional attention to the health and comfort of its employees and therefore decided to treat highly complex water (according to chemical parameters). Our company was pleased to accept the challenge and successfully resolve this issue.

The Customer’s requirements were clear and well defined, yet challenging to implement. Our specialists were required to ensure a continuous 24/7 supply of purified water for 70 employees and to treat 3 m³ of water per day.

The process of developing the technical solution was lengthy and took more than 8 months. During this period, numerous professional engineering solutions were proposed. One of these solutions was ultimately implemented according to the following scheme:

• Stage 1 – removal of mechanical impurities, sand, and rust using disc filters with a filtration rating of 130 µm.

• Stage 2 – water disinfection. A sodium hypochlorite solution is dosed into the treated water proportionally to the flow rate for oxidation of iron, manganese, and water disinfection.

• Stage 3 – removal of mechanical impurities, sand, rust, and scale. Protection of the main equipment against damage, filtration rating 20 µm (existing equipment).

• Stage 4 – adsorption treatment to remove iron, hydrogen sulfide, chlorine, organochlorine compounds, unpleasant odors, and to improve the organoleptic properties of water.

• Stage 5 – comprehensive water treatment to remove hardness salts, organic impurities, iron, manganese, and ammonium compounds using a universal water treatment unit.

• Stage 6 – water softening by removal of hardness salts using a strong acid cation exchange resin Dowex (USA).

During water filtration through the cation exchange resin, hardness ions Ca²⁺ and Mg²⁺ are replaced with Na⁺ ions. (Water softening to 0.02–0.4 mmol/dm³).

The specialists of our company carried out installation and commissioning works of the water treatment system and brought it into operational mode. Qualified personnel and technical engineers also conducted training for the Customer’s responsible staff on equipment operation and maintenance.

ZIKO takes on all solutions, even those others refuse to implement. Customers confidently entrust us with their water. In a market filled with inefficient and unattractive solutions, our company’s approach is not about selling more products, but about improving people’s health and well-being by providing clean, healthy, and high-quality drinking water. The company cares for our planet just as much as it cares for the drinking water that enters your home and is treated by drinking water systems.

If you are interested in a project like this, you can contact us in any convenient way via the “Contacts” section. Our managers will be happy to answer all your questions.

- Published in Наші клієнти

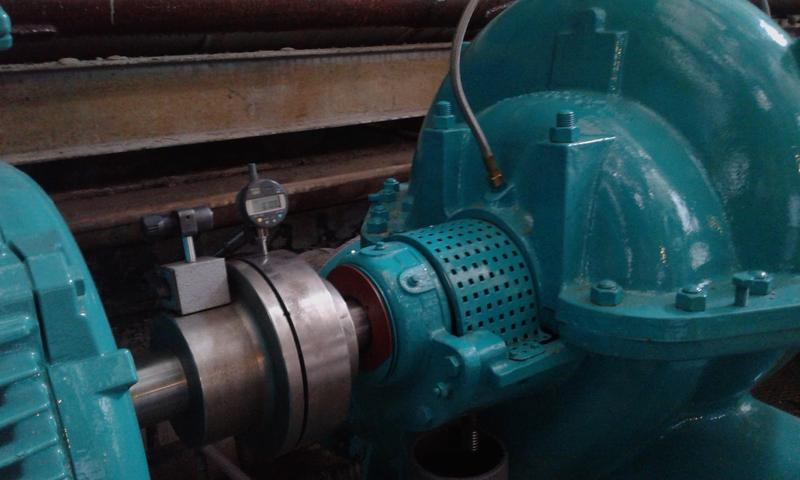

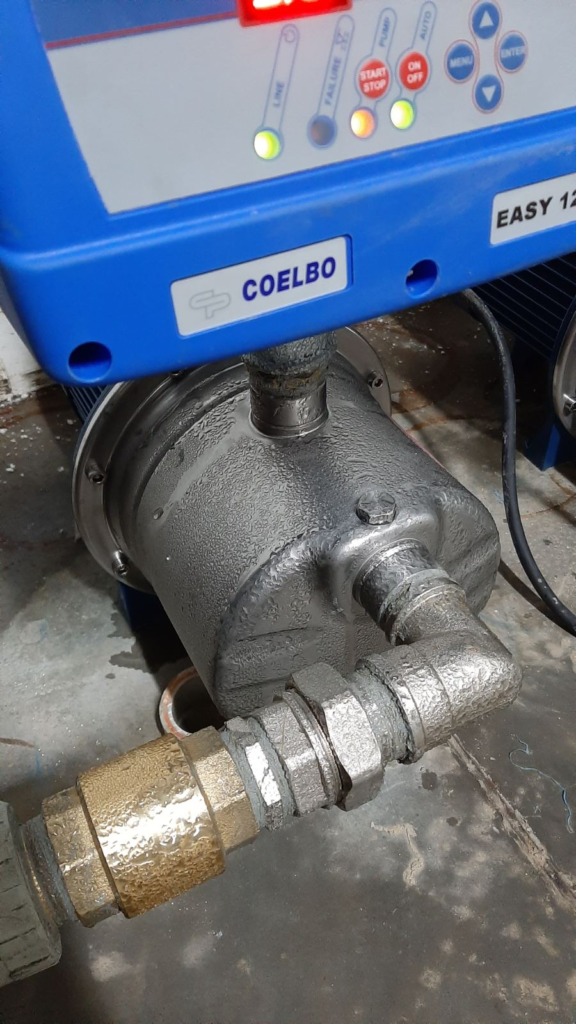

NOVOIAVORIVSKA CHP PLANT

Pumping Equipment for the Novoiavorivsk CHP Plant

ZIKO develops and implements complex engineering solutions using pumping equipment for entire residential districts, cities, towns, as well as power plants, water utilities, and other infrastructure facilities. The Novoiavorivsk CHP Plant required modernization of its pumping equipment.

The developed engineering solution included:

Wilo pumping stations for high-performance water supply.

- Published in Наші клієнти

WATER TREATMENT PROJECT FOR A HIGHER EDUCATIONAL INSTITUTION OF THE MINISTRY OF INTERNAL AFFAIRS OF UKRAINE

Water Treatment Project for a Higher Educational Institution of the Ministry of Internal Affairs of Ukraine

Water treatment challenges arise not only in private houses, apartments, and industrial facilities, but also in educational institutions, where access to clean water is equally essential. Many Ukrainian educational institutions use water supplied from municipal water networks or wells that is unsuitable for consumption. This water is used for cooking, drinking, as well as for hygienic and domestic needs.

ZIKO received a request to implement a water treatment solution for one of the higher educational institutions of the Ministry of Internal Affairs of Ukraine. The analyzed water showed excessive levels of hardness salts and iron. A specific feature of this project was that the reconstruction of the water treatment facilities was funded by the Embassy of the United States of America in Ukraine, which closely cooperates with this educational institution.

ZIKO implements engineering solutions for Ukrainian schools almost every month and already has extensive experience in preparing water of the highest quality. Thanks to this approach, pupils, students, teachers, and lecturers gain access to clean drinking water.

With the support of the U.S. Government and the U.S. Embassy in Ukraine, ZIKO fully designed and implemented a large-scale project for drinking and domestic water treatment. Company engineers visited the educational institution, conducted an analysis of the source water in our in-house laboratory, and developed a comprehensive, customized engineering solution for water treatment.

The ZIKO solution includes:

- Inline coarse mechanical water filters (130 µm) that retain large contaminants and extend the service life of downstream filtration equipment

- Fine mechanical inline filters for removal of remaining fine contaminants and preparation of water for comprehensive treatment

- Comprehensive domestic water treatment systems that remove hardness salts, iron, and ammonium, bringing water into compliance with domestic and utility standards

Such water significantly extends the service life of heating systems and plumbing equipment, protecting them from scale formation and clogging

After that, the water is directed to adsorption filters, which ensure the absence of chlorine and organochlorine compounds.

At the final stage, water is supplied to high-performance reverse osmosis systems for drinking water, which further purify water from all impurities and bacteria, making it suitable for consumption. Reverse osmosis systems use semi-permeable membranes capable of retaining even the smallest particles. This water treatment technology provides high efficiency (approximately 99.5%) with relatively low operating costs.

To ensure water safety and the absence of viruses and bacteria, the system is additionally equipped with a UV disinfection unit, which neutralizes most known bacteria and viruses by exposing water to ultraviolet radiation.

The entire water treatment solution is also supplemented with equipment that ensures uninterrupted water supply and a резерв water reserve in case of outages, including:

- German-made Wilo pumping stations for distribution of treated water. These pumps are characterized by high power, long service life, and compact dimensions, making them highly востребовані for large facilities

- Plastic storage tanks for accumulation of treated water. Thanks to specially selected materials used in their manufacture, water remains suitable for consumption for a longer period

Our team personally carried out installation and commissioning works to ensure the highest quality of the final result. Thanks to the successfully implemented solution, another educational institution can be confident in the safety of the water consumed by its students. ZIKO continuously monitors the operation of water treatment systems and regularly performs service maintenance to guarantee consistently high water quality.

If you have any additional questions or require a consultation regarding the individual selection of water treatment systems, please contact us using the available contact details, and our managers will assist you in selecting water treatment systems tailored to your specific requirements.

- Published in Наші клієнти

VERTOGRAND JUICE — PRODUCTION OF CONCENTRATED JUICES

Water Treatment for Juice Production in Irpin

Vertograd Juice is a Ukrainian company specializing in the production of concentrated fruit and vegetable juices and purées. The company operates three large processing plants located in the Kyiv, Khmelnytskyi, and Chernivtsi regions, producing direct-pressed juices, fruit purées, and frozen fruits and vegetables. The core principles of Vertograd Juice are quality, control, and production safety, as a significant portion of its products is exported to EU countries, Asia, the USA, and other markets. At every stage of juice and purée production, water of different treatment levels is used. A distinctive feature of Vertograd Juice, setting it apart from others, is the presence of its own plantations, the largest being an apple orchard covering 250 hectares, where fruits and vegetables for juice production are grown.

Juice production requires large volumes of water throughout the entire technological process. Properly treated process water is a key factor in ensuring high product quality. Unfortunately, raw water quality often does not meet production requirements. Therefore, large food-processing enterprises install water treatment systems for production processes. Such systems remove hardness salts, iron, nitrates, sulfates, hydrogen sulfide, and other harmful impurities. Individual water treatment systems are developed for each enterprise based on specific requirements.

As the geography of product exports continues to expand, the need to comply with increasingly stringent standards grows accordingly. For this reason, Vertograd Juice set a goal to achieve high quality standards for its products.

That is why Vertograd Juice approached ZIKO with a request to restore production at another specialized plant and to select a high-quality water treatment system. Water treatment was required both for technological processes (steam generators for juice concentrate production) and for heating systems, in order to minimize operating costs and extend equipment service life.

ZIKO specialists visited the plant, conducted a free water analysis, and developed a customized solution using modern water treatment systems for wastewater treatment in large-scale production processes.

To implement this engineering solution, specialized water treatment equipment was manufactured and installed at the plant, including:

- Ecosoft MO 9 MAXI industrial reverse osmosis system with a capacity of 30 m³/h. This is a modern and efficient method of water treatment for industrial facilities. The system removes up to 99% of all impurities, ensuring good water taste and, as a result, excellent quality of the final product.

- Comprehensive water treatment system for pre-treatment prior to reverse osmosis. This system is suitable for facilities where water contains high levels of salts, iron, and other organic impurities. Unlike its analogues, the treatment process is performed in a single stage.

- Reconstruction of the chemical water treatment unit for the steam boiler house, which minimizes salt content and increases the performance and service life of steam generators.

- Wilo pumping equipment for wastewater treatment and discharge. The advantages of this pumping equipment include compact dimensions, long service life, and proven German quality.

ZIKO specialists regularly service this equipment and periodically replace membranes in the reverse osmosis system.

If you are interested in the implementation of this project or have any questions, please visit the “Contacts” section to write or call us. Our qualified specialists will be happy to answer all your questions and help you select a water treatment system tailored to your specific needs.

- Published in Наші клієнти

MEAT AND DAIRY PROCESSING PLANT “AGRO-POBUT-SERVICE”

Water Treatment at the Agro-Pobut-Service Meat and Dairy Processing Plant

Agro-Pobut-Service is a meat and dairy processing plant known for the production of cheeses and other products within this sector. Understanding the importance of complying with regulatory requirements and production technologies, the company decided to install water treatment and water conditioning systems. Few people realize that the quality of treated water directly affects the taste and organoleptic properties of the final products.

When developing the engineering solution, ZIKO took into account all specifics of the technological process, the required capacity, and the quality of the source water. It was decided to use the following equipment:

- Comprehensive water treatment system based on Ecomix media

- Industrial reverse osmosis system

- Ultraviolet water disinfection system

Thanks to the implemented engineering solution, Agro-Pobut-Service customers can enjoy products manufactured using high-quality drinking water.

- Published in Наші клієнти

VOLODYMYR-VOLYNSKYI VODOKANAL

Water treatment systems for the municipal water utility in the city of Volodymyr-Volynskyi

The Volodymyr-Volynskyi Vodokanal approached the company “ZIKO” with a request to reconstruct the water supply and water treatment system to meet the needs of the municipal community. The engineered solution included the use of the following equipment:

- Industrial integrated water treatment systems Ecosoft

- Wilo pumping stations

- Water storage tanks

Installation, technical, and commissioning works were also carried out by the service and technical personnel of the company “ZIKO”.

As a result, all residents of the city of Volodymyr-Volynskyi can now use treated drinking water with an optimal level of water supply quality.

- Published in Наші клієнти

NOBILIS – HOTEL COMPLEX

Water treatment systems for the Nobilis Hotel in the city of Lviv

The Nobilis hotel complex is located in Lviv near the historical city center. It is the only small world-class hotel in the city providing a full range of services. Nobilis has been operating since 2011 and currently offers a total of 49 rooms across different price categories. Hotel guests can visit the SPA center, fitness room, lounge bar, and restaurant. Visits to Nobilis are also included in various excursion tours as a notable tourist attraction of the city. Accordingly, a hotel of this class must provide its guests with clean drinking water and ensure high quality of all water-dependent services.

Advantages of water treatment systems in hotel complexes

Most hotels, including Nobilis, use water supplied from the municipal water network. Clean water for hotels and restaurants is a key factor for successful operation, as hotels are a critical component of the tourism industry, serving both leisure and business travelers. Properly designed water supply and filtration systems help prevent many operational issues related to equipment in the future. The installation of industrial water filtration systems resolves all issues associated with drinking and technical water in hotels and restaurants.

Water treatment technologies

The selection of water filtration systems should be entrusted to specialists. For this reason, the management of the Nobilis hotel approached the company ZIKO with a request to design and install a high-quality water supply and water filtration system for the hotel complex.

ZIKO specialists conducted water analysis, inspected plumbing conditions, and most importantly — assessed the needs of hotel guests.

The engineering solution by ZIKO includes:

- Six column-type water treatment filters Ecosoft FK1252 based on Ecosoft filter media. These filters remove hardness salts, manganese, ammonium, and organic compounds from water.

- German-manufactured Wilo pumping stations featuring low energy consumption and long service life.

- A plastic water storage tank manufactured by UkrKhimPlast to maintain water supply during peak consumption periods. The tanks are produced using rotational molding technology, are corrosion-resistant compared to metal alternatives, have lower weight, and offer a longer operational lifespan.

Various water filtration systems are used for water treatment, depending on their application. For example, technical water for dishwashing or laundry and drinking water for food preparation require different purification methods.

Mechanical filtration — used to remove solid and organic contaminants such as sand, rust, and similar particles. This is one of the mandatory stages of water treatment.

Water softening and iron removal — during this stage, hardness salts are removed from the water. Softened water does not form scale or limescale deposits.

Reverse osmosis — the most effective technology for drinking water purification. Water passes through specialized membranes that retain all impurities. As a result, the water achieves improved taste and clarity.

Engineers regularly monitor the operation of the installed equipment and replace filter media as required.

Thanks to the successfully implemented solution, the Nobilis hotel provides its guests and staff with high-quality, clean water.

If you have any questions regarding the implementation of this project or your own requirements, please contact us using the available contact details, and our qualified managers will provide comprehensive answers and assist in selecting the optimal water treatment system for your needs.

- Published in Наші клієнти

ATLAS – HOTEL COMPLEX

Professional water treatment systems for the Atlas Hotel in the city of Lviv

The Atlas Deluxe hotel complex is located in the very center of the historic part of Lviv, where the city’s cultural life is most vibrant. The building itself was constructed in 1909 in the Art Nouveau style with romantic medieval stylization. Today, it is an elegant four-star hotel offering 42 rooms designed in a classic style and equipped with spacious marble bathrooms. Guests are provided with a range of additional services, including large conference halls for conferences or seminars, as well as a European cuisine restaurant, distinguished by dishes prepared on lava stone.

Water treatment in hotels and restaurants

High water quality is an essential condition for the well-being and comfort of hotel guests. In addition, water parameters directly affect color, odor, and the taste of prepared food and beverages. To improve water quality, various water treatment systems and filters are used, which are selected individually after preliminary water analysis. Water treatment systems are applied not only in private houses or large industrial facilities, but also in hotels, restaurants, and cafés — this is a mandatory condition for efficient operation and customer satisfaction. A satisfied customer is more likely to return. Moreover, the use of such systems is an economically efficient solution.

Advantages of water treatment systems in hotels:

- No scale or deposits remain in bathrooms. Softened water without unpleasant odors or mechanical impurities does not leave yellowish stains or limescale, thereby extending the service life of sanitary equipment.

- Tasty food and perfectly clean tableware in restaurants. When treated water is used, the quality of prepared food improves, and dishwashers operate more efficiently, require less detergent, and do not leave white residue on dishes.

- Laundry remains bright white. Low water hardness ensures better washing performance, improved stain removal, does not degrade fabric appearance, reduces detergent consumption, and increases detergent efficiency.

- Increased efficiency of boiler rooms and extended service life of heating equipment. Treated water does not contain hardness salts that would otherwise accumulate inside pipes over time.

The Atlas Deluxe hotel approached the company “ZIKO” with a request for drinking water analysis and the selection of a water treatment system. Understanding the importance of caring for both guests and their own equipment, the hotel required comprehensive water treatment, including the removal of harmful impurities such as iron and hardness salts from tap water.

Specialists from the company “ZIKO” visited the hotel, conducted water analysis in their own laboratory, calculated the required water consumption volumes, and, based on the initial water quality parameters, developed an optimal engineering solution for water treatment in the hotel using modern water treatment systems.

The solution provided by the company “ZIKO” includes:

- Installation of a German-made Wilo pumping station, featuring compact dimensions, low energy consumption, reduced operating costs, long service life, reliability, and advanced technological design.

- Installation of a BB10 pre-mechanical filtration filter designed for domestic water treatment.

- Installation of a comprehensive water treatment system based on Ecomix, intended for the treatment of water with high concentrations of hardness salts and various organic impurities.

The use of treated water helps prevent scale formation, improves organoleptic properties, and extends the service life of sanitary equipment in the hotel.

The company “ZIKO” continuously monitors the operation of water treatment systems and regularly performs maintenance services to ensure consistently high quality.

Thanks to the installed equipment, Atlas Deluxe provides all hotel guests with purified drinking water.

If you are interested in this comprehensive water treatment solution, please contact us using the information available in the “Contacts” section — by email, phone, or by submitting a callback request. Our managers will answer all your questions and assist in selecting the most suitable water treatment equipment for your needs.

- Published in Наші клієнти

PRAVDA BEER THEATRE – RESTAURANT AND BREWERY

Water treatment for beer production / brewery at the PRAVDA Beer Theatre, city of Lviv

The PRAVDA Beer Theatre is a popular food service venue operated by the LOKAL network in Lviv, located in the very center of the city on Rynok Square. PRAVDA is not just a restaurant or a brewery plant. PRAVDA is a beer theatre, where visitors can watch food preparation and beer brewing in an open kitchen format and enjoy performances by the in-house brass band, the PRAVDA Orchestra. Guests can also take guided tours of the brewery and taste freshly brewed beer directly from the fermentation tank.

Moreover, the PRAVDA Beer Theatre is a local brewery offering customers beer produced on-site. Few people realize that brewing specific beer styles requires properly prepared water as a prerequisite.

Water requirements for beer brewing

Water is the primary component in beer brewing, and its quality has a significant impact on the taste of the final product. First and foremost, drinking water must comply with the general sanitary requirements approved by hygienic standards for potable water intended for human consumption. However, these standards are general in nature and do not fully meet the specific requirements for brewing water, which differ depending on beer production processes.

Key water parameters for brewing:

- Low nitrate content, as nitrates are already present in hops.

- Low chloride content.

- Presence of magnesium (Mg); higher magnesium levels increase beer bitterness.

- Low total salt content, otherwise the beer may taste salty.

- Minimal content of carbohydrate compounds.

Each beer style has its own brewing requirements and technologies. In some cases, adding specific mineral components to water is sufficient to significantly alter the beer’s flavor profile.

For example:

- Total hardness affects wort pH due to reactions of calcium and magnesium phosphate salts extracted from malt.

- Higher Mg²⁺ content enhances aroma, increases astringency, and adds a bitter aftertaste (Mg²⁺ acts as an enzyme activator).

- Low Ca²⁺ content makes beer more bitter and cloudy. The ideal calcium-to-magnesium ratio is 2:1.

- Sodium (Na) content, depending on concentration, can impart either acidic or salty flavors.

- Acidity level (pH) below 4.0 produces a sour taste and intensifies bitterness perception. The optimal pH range is 6.8–7.0.

- Iron (Fe) / manganese (Mn) negatively affect beer quality, causing astringent taste and foam turbidity.

- Trace elements such as Zn and Mn²⁺ are required for yeast growth, while Fe²⁺ and Fe³⁺ participate in redox enzymatic reactions.

- Sulfates (SO₄²⁻) affect proteins and lipids formed during fermentation of hydrogen sulfide and sulfur dioxide, contributing to a bitter, dry, and harsh beer taste.

- Chlorides (Cl⁻) reduce and soften beer bitterness.

The PRAVDA Beer Theatre set the goal of providing visitors with purified drinking water and, as a result, refined and high-quality beer. The best flavor can only be achieved using properly treated water. Beer at PRAVDA is considered craft beer, as it is brewed in small batches, allowing control over every production stage and strict adherence to technology. PRAVDA is the only brewery in Ukraine using double fermentation technology. After brewing and maturation, the beer is bottled with a small addition of sugar and yeast, enabling natural carbonation through secondary fermentation inside sealed bottles. This process allows longer storage compared to other beers while preserving taste and quality. Part of the production is exported to Italy, the Czech Republic, the United Kingdom, Canada, and other European countries.

At PRAVDA, beer is brewed by leading brewers from Ukraine, Belgium, the Czech Republic, and the United States. Each beer style has its own brewing technology and ingredients, and therefore requires different water quality parameters and mineral composition. For this reason, PRAVDA approached the company ZIKO for a free water analysis and the selection of a water treatment system tailored specifically to their brewing profile, ensuring the ability to serve truly exceptional beer.

Specialists from the company ZIKO visited the brewery and developed a specialized engineering solution using modern water treatment systems, ensuring high quality and excellent flavor characteristics across all brewed beer varieties.

The engineering solution for the PRAVDA Beer Theatre includes:

- Mechanical filtration systems that remove suspended solids such as silt, sand, and rust from water.

- Comprehensive water treatment systems based on Ecomix filter media, which remove high concentrations of hardness salts, iron compounds, ammonium, manganese, and organic impurities.

- Pumping equipment for water supply, water treatment, and wastewater processing.

- Ultraviolet water treatment systems for the removal of organic contaminants.

- Water storage tanks to ensure continuous supply of treated water.

As a result, the PRAVDA Beer Theatre can guarantee excellent beer quality brewed using purified water.

ZIKO regularly provides maintenance services for this project and performs ongoing monitoring of equipment operation.

If you are interested in a similar project, please contact us using any convenient method listed in the “Contacts” section. Our managers will be happy to answer all your questions.

- Published in Наші клієнти

LLC “HUBYN POULTRY COMPLEX”

Water treatment system for LLC “Hubyn Poultry Complex”

LLC “Hubyn Poultry Complex” is an enterprise specializing in poultry farming, as well as the production and sale of poultry meat. LLC “Hubyn Poultry Complex” is part of the agro-industrial group “Pan Kurchak”. All enterprises of the agro-industrial group are located within the Volyn region, which enables full control over production processes and the ability to implement changes at every stage of production. The agro-industrial group includes companies specializing in grain cultivation, feed production and distribution, broiler chick incubation, poultry meat production, pig farming, pork processing, and sausage manufacturing.

LLC “Hubyn Poultry Complex” operates six active poultry farms located across four districts of the Volyn region. Each farm is equipped with modern equipment from leading global manufacturers. The broiler growing process is highly automated, with production processes monitored using computer-based control systems. The company’s product range includes more than 40 items available in chilled and frozen form. During production, poultry meat undergoes a series of sequential processing stages, ensuring maximum preservation of freshness and taste characteristics.

Products of LLC “Hubyn Poultry Complex” comply with all international quality standards, as confirmed by relevant certifications. A portion of frozen products is exported to more than 50 countries across Europe, Asia, and Africa.

As production volumes increased, the management of the poultry complex approached the company “ZIKO” to conduct water analysis and to select and install industrial water treatment systems.

A key feature of this project was the selection of systems for cold water treatment (approximately 1°C). Cold water is rarely suitable for treatment using conventional filtration systems, as the efficiency of chemical reactions decreases significantly at low temperatures, not to mention the increased risk of equipment malfunction. On the other hand, heating large volumes of water would have significantly increased operational costs.

Specialists from the company “ZIKO” visited the facility, conducted an audit of the existing equipment, and analyzed the incoming water. To develop the solution, ZIKO engineers and chemists carried out proprietary research on various cold water filtration methods and designed an individualized engineering solution for cold water treatment at LLC “Hubyn Poultry Complex” without prior water heating.

At the facility, ZIKO specialists implemented the following water treatment technology:

- First stage — removal of mechanical impurities, sand, and rust using disc filters with a filtration rating of 130 microns.

- Second stage — comprehensive water treatment to remove hardness salts, organic impurities, iron compounds, manganese, and ammonium using a universal water treatment unit.

- Third stage — water disinfection using an ultraviolet (UV) sterilizer.

Under the service agreement, ZIKO service engineers will carry out regular inspections and monitoring of the installed equipment.

If you are interested in the implementation of this project or have additional questions, you may contact us using the available Contact details. Our managers will provide comprehensive answers and assist in selecting water treatment systems according to your specific parameters.

- Published in Наші клієнти

- 1

- 2